1L FPC led lighting Light bar board

Item No.: F000126

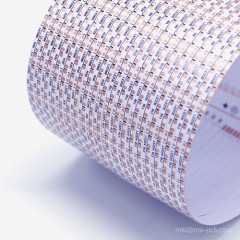

Single‑layer flexible circuit board for LED light bars, crafted for slim profile and uniform illumination, compatible with custom pcb layout services and pcb maker online requirements.

Description

Light Bar Design and Construction

The 1L FPC light bar board is a flexible circuit board designed as a single conductive layer (single‑layer FPC) for LED lighting applications. Its construction features a thin, bendable substrate suitable for linear illumination arranged in a bar form. Conductive copper traces form the electrical paths for LED mounting, with solderable pads where LEDs attach. The board keeps a minimal total thickness consistent with single‑layer FPC norms, reducing bulk in lighting fixtures. Insulation or coverlay layers protect exposed copper from moisture or oxidation. This design is typical of boards produced by experienced pcb manufacturers who supply simple but reliable single‑layer FPCs for lighting. Such a board is especially useful when light distribution must be even along the bar without secondary reflections or shadows, relying on uniform trace layout and consistent copper‑width to maintain current flow across the board.

Electrical and Thermal Behavior

Because this is a single‑layer flexible printed circuit, current distribution depends on trace width, copper thickness, and layout uniformity. Although single layer means fewer copper paths and potential current limitations compared to multilayer designs, this board is optimized for LED lighting where power demands are moderate and controlled. Thermal dissipation is managed by limiting heat generation via appropriate trace geometry (width, spacing) and ensuring that LEDs are mounted evenly, avoiding hot spots. The flexibility of the substrate allows installation in fixtures where bending or mechanical alignment is required, but layout ensures that bending zones are minimized to reduce stress on copper. The board must maintain electrical continuity and insulation under such mechanical constraints. These features are relevant to both pcb layout services and customers using pcb maker online platforms who need predictable electrical behavior in lighting bars.

Manufacturing Process and Quality Assurance

Meidear’s production of this 1L FPC LED lighting light bar board follows standard flexible PCB fabrication methods: copper patterning for the single layer, substrate preparation, lamination (if applicable), solder mask or protective finish on solder pads, and inspections. Visual inspection checks for defects in copper traces or solder pad uniformity. Dimensional checks ensure board width, pad locations, and overall length of the light bar match customer specifications. Electrical tests confirm continuity across traces and correct solderability of LED pads. Bending or flex tests may verify mechanical compliance if the product is to be installed on curved surfaces. These steps align with practices offered by recognized pcb manufacturers and service providers of flex pcb boards, as well as online ordering workflows in pcb maker online systems.

Product Advantages

Minimal Thickness for Sleek LED Fixtures

The single‑layer design reduces overall thickness and weight of the board, permitting integration into slim light bar housings where space is limited. With fewer layers, material stack‑up is simpler, which reduces risk of delamination and production cost. Uniform copper trace layout and minimal insulation layers preserve slim form while maintaining performance. For designers focused on minimal profile lighting fixtures, this advantage is critical. Projects using flex board pcb solutions benefit from this thin form factor.

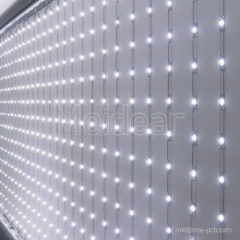

Uniform Illumination with Predictable Current Flow

By using consistent trace widths and well‑spaced copper paths, this board supports even power delivery across the LED mounting points, reducing brightness variation along the bar. The layout avoids sudden changes in trace width or sharp angles that can cause voltage drop or uneven heat accumulation. As a result, LED modules mounted along the bar show more uniform light output. This is important in lighting design where appearance matters, and aligns with expectations from pcb layout services specifying precise voltage drop tolerances.

Cost‑Effective Single‑Layer FPC Production

Single‑layer FPCs have simpler fabrication demands compared to multilayer or heavy copper flex boards. Fewer lamination steps, simpler masking and solder pad exposure requirements, and less complex internal routing reduce production time and cost. For clients ordering via pcb maker online systems or those sourcing through pcb manufacturers with volume considerations, this board offers a balance of performance and expense. It suits applications where high current density or multilayer stacking is not required, and where rapid manufacturing turnaround is desired without over‑engineering.

Use Scenarios

Architectural Lighting Strips

In architectural lighting applications—such as under‑cabinet lighting, wall wash lighting, or cove lighting—this board can be mounted behind diffusers in aluminum extrusion light bars. During installation, the FPC light bar board is fixed inside the housing and LEDs mounted along its length. The slim and single‑layer nature reduces heating behind the diffuser and allows for efficient heat transfer through the housing. This scenario demonstrates how uniform trace layout and protection of solder joints help maintain consistent lighting over long runs, especially in architectural design that demands clean lines and discreet light sources. Here, customers ordering from pcb manufacturers or using pcb maker online platforms expect reliability in long strips with minimal visual defects.

Retail Display and Signage

Light bars in retail display cases or store signage often require bright, even lighting in a linear bar shape. The board is used to mount LEDs spaced to match the visual requirements of the display, ensuring that light spreads evenly across shelf edges or product features. Because signs may run for many hours, electrical reliability and consistency are key—trace layout uniformity and solder pad integrity affect longevity. When integrated into signage modules, board mounting may require fixing at the ends or along the back to preserve straightness. In such usages, flex pcb boards designed correctly for lighting help reduce shadowing and ensure brightness consistency, meeting design specifications provided by layout services or manufacturers.

Custom Lighting Fixtures and Interior Design Elements

Interior lighting elements—such as accent light bars, thin light panels, or embedded furniture lighting—require boards that conform to custom lengths or shapes. The single‑layer light bar board supports custom cutting or length specification, solder pad positioning, and consistent illumination across customized lengths. Designers and lighting engineers using pcb layout services or fetching boards via pcb maker online workflows rely on precise board layout so that LEDs can be mounted, powered, and enclosed in clean fixtures. These fixtures often require that boards be installed behind diffusers or within narrow grooves, where minimal thickness and reliable performance under slight bending are essential.

About Us

Meidear produces flexible and rigid printed circuit boards, with expertise in single‑layer and multilayer flex pcb products, LED lighting boards, and custom FPC designs. Capabilities include substrate handling, copper patterning, lamination, coverlay or solder pad finishing, and protective insulation for conductive paths. Quality assurance includes visual and dimensional inspections, electrical continuity testing, and mechanical reliability checks. Support is offered for clients needing pcb layout services and sourcing through pcb maker online, from prototyping to production volumes. Meidear operates with technical precision to serve industries where lighting, display, or compact electronics are integrated, providing consistent and manufacturable designs by experienced pcb manufacturers.

FAQ

What construction does this light bar board use?

It uses a single‑layer flexible printed circuit with one copper conductor path layer, solder pads for LED attachment, and protective finish on exposed copper.

How does this board maintain uniform illumination across long lengths?

Uniform trace width and even spacing of copper paths help minimize voltage drop and prevent brightness fall‑off; design layout ensures consistent current distribution along the entire light bar.

Can layout customizations be made through pcb layout services?

Yes, Meidear supports custom trace routing, LED pad placement, board length adjustment, and other layout specifications via professional pcb layout services.

Is this product available for small orders via pcb maker online?

Yes, Meidear handles both small‑quantity and larger production through online ordering or inquiry workflows for this type of LED light bar flexible board.

What protective finishes are applied to ensure reliability in LED lighting use?

Finishes such as solderable pad exposure, coverlay or protective mask, and insulating coatings protect copper from oxidation, moisture, and environmental wear, helping maintain performance in lighting applications.

Submit your LED light bar design for a custom single‑layer flex PCB quote today!

The 1L FPC light bar board is a flexible circuit board designed as a single conductive layer (single‑layer FPC) for LED lighting applications. Its construction features a thin, bendable substrate suitable for linear illumination arranged in a bar form. Conductive copper traces form the electrical paths for LED mounting, with solderable pads where LEDs attach. The board keeps a minimal total thickness consistent with single‑layer FPC norms, reducing bulk in lighting fixtures. Insulation or coverlay layers protect exposed copper from moisture or oxidation. This design is typical of boards produced by experienced pcb manufacturers who supply simple but reliable single‑layer FPCs for lighting. Such a board is especially useful when light distribution must be even along the bar without secondary reflections or shadows, relying on uniform trace layout and consistent copper‑width to maintain current flow across the board.

Electrical and Thermal Behavior

Because this is a single‑layer flexible printed circuit, current distribution depends on trace width, copper thickness, and layout uniformity. Although single layer means fewer copper paths and potential current limitations compared to multilayer designs, this board is optimized for LED lighting where power demands are moderate and controlled. Thermal dissipation is managed by limiting heat generation via appropriate trace geometry (width, spacing) and ensuring that LEDs are mounted evenly, avoiding hot spots. The flexibility of the substrate allows installation in fixtures where bending or mechanical alignment is required, but layout ensures that bending zones are minimized to reduce stress on copper. The board must maintain electrical continuity and insulation under such mechanical constraints. These features are relevant to both pcb layout services and customers using pcb maker online platforms who need predictable electrical behavior in lighting bars.

Manufacturing Process and Quality Assurance

Meidear’s production of this 1L FPC LED lighting light bar board follows standard flexible PCB fabrication methods: copper patterning for the single layer, substrate preparation, lamination (if applicable), solder mask or protective finish on solder pads, and inspections. Visual inspection checks for defects in copper traces or solder pad uniformity. Dimensional checks ensure board width, pad locations, and overall length of the light bar match customer specifications. Electrical tests confirm continuity across traces and correct solderability of LED pads. Bending or flex tests may verify mechanical compliance if the product is to be installed on curved surfaces. These steps align with practices offered by recognized pcb manufacturers and service providers of flex pcb boards, as well as online ordering workflows in pcb maker online systems.

Product Advantages

Minimal Thickness for Sleek LED Fixtures

The single‑layer design reduces overall thickness and weight of the board, permitting integration into slim light bar housings where space is limited. With fewer layers, material stack‑up is simpler, which reduces risk of delamination and production cost. Uniform copper trace layout and minimal insulation layers preserve slim form while maintaining performance. For designers focused on minimal profile lighting fixtures, this advantage is critical. Projects using flex board pcb solutions benefit from this thin form factor.

Uniform Illumination with Predictable Current Flow

By using consistent trace widths and well‑spaced copper paths, this board supports even power delivery across the LED mounting points, reducing brightness variation along the bar. The layout avoids sudden changes in trace width or sharp angles that can cause voltage drop or uneven heat accumulation. As a result, LED modules mounted along the bar show more uniform light output. This is important in lighting design where appearance matters, and aligns with expectations from pcb layout services specifying precise voltage drop tolerances.

Cost‑Effective Single‑Layer FPC Production

Single‑layer FPCs have simpler fabrication demands compared to multilayer or heavy copper flex boards. Fewer lamination steps, simpler masking and solder pad exposure requirements, and less complex internal routing reduce production time and cost. For clients ordering via pcb maker online systems or those sourcing through pcb manufacturers with volume considerations, this board offers a balance of performance and expense. It suits applications where high current density or multilayer stacking is not required, and where rapid manufacturing turnaround is desired without over‑engineering.

Use Scenarios

Architectural Lighting Strips

In architectural lighting applications—such as under‑cabinet lighting, wall wash lighting, or cove lighting—this board can be mounted behind diffusers in aluminum extrusion light bars. During installation, the FPC light bar board is fixed inside the housing and LEDs mounted along its length. The slim and single‑layer nature reduces heating behind the diffuser and allows for efficient heat transfer through the housing. This scenario demonstrates how uniform trace layout and protection of solder joints help maintain consistent lighting over long runs, especially in architectural design that demands clean lines and discreet light sources. Here, customers ordering from pcb manufacturers or using pcb maker online platforms expect reliability in long strips with minimal visual defects.

Retail Display and Signage

Light bars in retail display cases or store signage often require bright, even lighting in a linear bar shape. The board is used to mount LEDs spaced to match the visual requirements of the display, ensuring that light spreads evenly across shelf edges or product features. Because signs may run for many hours, electrical reliability and consistency are key—trace layout uniformity and solder pad integrity affect longevity. When integrated into signage modules, board mounting may require fixing at the ends or along the back to preserve straightness. In such usages, flex pcb boards designed correctly for lighting help reduce shadowing and ensure brightness consistency, meeting design specifications provided by layout services or manufacturers.

Custom Lighting Fixtures and Interior Design Elements

Interior lighting elements—such as accent light bars, thin light panels, or embedded furniture lighting—require boards that conform to custom lengths or shapes. The single‑layer light bar board supports custom cutting or length specification, solder pad positioning, and consistent illumination across customized lengths. Designers and lighting engineers using pcb layout services or fetching boards via pcb maker online workflows rely on precise board layout so that LEDs can be mounted, powered, and enclosed in clean fixtures. These fixtures often require that boards be installed behind diffusers or within narrow grooves, where minimal thickness and reliable performance under slight bending are essential.

About Us

Meidear produces flexible and rigid printed circuit boards, with expertise in single‑layer and multilayer flex pcb products, LED lighting boards, and custom FPC designs. Capabilities include substrate handling, copper patterning, lamination, coverlay or solder pad finishing, and protective insulation for conductive paths. Quality assurance includes visual and dimensional inspections, electrical continuity testing, and mechanical reliability checks. Support is offered for clients needing pcb layout services and sourcing through pcb maker online, from prototyping to production volumes. Meidear operates with technical precision to serve industries where lighting, display, or compact electronics are integrated, providing consistent and manufacturable designs by experienced pcb manufacturers.

FAQ

What construction does this light bar board use?

It uses a single‑layer flexible printed circuit with one copper conductor path layer, solder pads for LED attachment, and protective finish on exposed copper.

How does this board maintain uniform illumination across long lengths?

Uniform trace width and even spacing of copper paths help minimize voltage drop and prevent brightness fall‑off; design layout ensures consistent current distribution along the entire light bar.

Can layout customizations be made through pcb layout services?

Yes, Meidear supports custom trace routing, LED pad placement, board length adjustment, and other layout specifications via professional pcb layout services.

Is this product available for small orders via pcb maker online?

Yes, Meidear handles both small‑quantity and larger production through online ordering or inquiry workflows for this type of LED light bar flexible board.

What protective finishes are applied to ensure reliability in LED lighting use?

Finishes such as solderable pad exposure, coverlay or protective mask, and insulating coatings protect copper from oxidation, moisture, and environmental wear, helping maintain performance in lighting applications.

Submit your LED light bar design for a custom single‑layer flex PCB quote today!