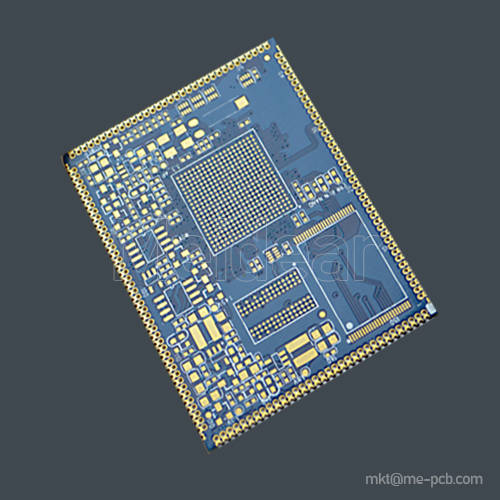

8L 1OZ 1.6mm Immersion Gold PCB

Get Latest Price

Min.Order Quantity:

5 Set/Sets

Supply Ability:

1000 Set/Sets per Month

Port:

Ningbo

Payment Terms:

L/C,T/T

This 8-layer PCB features a compact stack-up optimized for advanced electronic devices requiring layered routing. The core material supports controlled impedance, helping engineers implement high-speed signal transmission without cross-interference. With pcb board design considerations in mind, the layer distribution ensures efficient layout for both power and ground planes. Using pcb layout services, clients can further refine trace width and layer transitions to meet exacting circuit requirements. The structural thickness of 1.6mm maintains rigidity while offering support for thermal dissipation paths, a critical aspect in tightly integrated systems.

Immersion Gold Finish for Long-Term Reliability

The board’s immersion gold finish enhances surface stability by preventing oxidation of exposed copper pads. This coating ensures consistent solderability, crucial for repeated reflow cycles or fine-pitch component mounting. The 1oz copper thickness ensures a robust current-carrying capacity, suitable for high-density power circuitry. With the support of pcb manufacturers, the immersion gold process is controlled through precise plating time and temperature adjustments to ensure uniform coverage. Clients ordering through pcb maker online portals receive finished boards that meet commercial-grade reliability benchmarks under various humidity and thermal conditions.

Dimensional and Material Precision

Measuring 1.6mm in overall thickness with tight tolerance control, this PCB provides dimensional stability for automated assembly lines. The substrate material, paired with precise via drilling, supports multilayer connectivity without compromising on interlayer adhesion. Engineers utilizing pcb layout services can take advantage of defined pad geometries and annular rings for secure component mounting. For applications requiring dependable signal integrity and voltage isolation, this flexible circuit board solution—despite being rigid in form—achieves electrical consistency through rigorous layout and copper distribution standards implemented by top-tier pcb manufacturers.

Product Advantages

1. Controlled Layer Stack for Signal Isolation

Each internal layer within the 8L configuration is purposefully assigned for signal, ground, or power distribution to maintain signal clarity. Layout engineers can use pcb layout services to enforce impedance control for differential signal pairs and route them on appropriate layers. The inclusion of ground shielding between high-frequency traces minimizes EMI, a concern in compact electronic builds. By leveraging stack design principles and support from pcb manufacturers, clients receive boards that exhibit minimized crosstalk and predictable electrical performance across temperature ranges.

2. Uniform Gold Deposition for Surface Planarity

The immersion gold layer is applied using tightly monitored chemical baths, ensuring consistent pad planarity across all exposed surfaces. This feature is especially important for fine-pitch SMT components, where flatness directly impacts solder joint reliability. With consistent thickness deposition, engineers can rely on the pad surface to perform across multiple assembly runs. Through pcb maker online channels, customers benefit from batch-level process control that maintains finish quality even during scale-up production. As a result, solder paste application, component pickup, and reflow integrity remain stable across production lots.

3. High Copper Weight for Thermal Efficiency

The 1oz copper layer ensures enhanced thermal conductivity within internal layers, aiding heat dissipation from power ICs or LED drivers. Heat-generating components placed on the top layer benefit from thermal vias that channel heat toward inner planes. Flex board pcb principles—though this board is rigid—are partially borrowed in via optimization to manage thermal gradients. This configuration improves product lifetime in high-current use cases. Leveraging design principles from flexible circuit board applications, Meidear integrates efficient copper usage with strategic plane distribution to maintain operating stability.

Use Scenarios

1. Precision Assembly in Multilayer Electronics

In electronics manufacturing setups where multi-layer PCBs are assembled using automated pick-and-place machines, dimensional accuracy and surface planarity become essential. This 8-layer board ensures pad uniformity and structural rigidity, enabling secure mounting of high-density QFNs or BGAs. Teams sourcing from pcb maker online platforms can expect lead-free compatibility and flux-resilient finishes suited for RoHS-compliant reflow. PCB board design strategies used in planning component distribution directly benefit from predictable soldering outcomes, especially in industrial control boards or communication backplanes.

2. Design Integration in Space-Constrained Systems

Compact control modules and embedded platforms often demand vertical signal routing within tight enclosures. The 8L format allows signal segregation across defined planes without increasing board footprint. Using pcb layout services, developers can balance mixed-signal separation while maintaining ground integrity. This board accommodates decoupling strategies, routing constraints, and thermal zoning—all while maintaining a thickness of 1.6mm. PCB manufacturers ensure that all layers are laminated under pressure and heat to avoid delamination during thermal cycling in operational environments.

3. Long-Term Operation in Electrical Equipment

In final products expected to operate for years without service, surface finish and copper stability are essential. Immersion gold ensures stable contact points for headers, connectors, or probes that interface repeatedly. Devices subjected to cyclic temperature exposure or vibration require multilayer boards that resist micro-cracking between vias or interconnects. Designed with pcb board design longevity in mind and manufactured through trusted pcb manufacturers, this PCB is ideal for measurement devices, industrial sensors, or long-life automation systems that prioritize reliability over cost.

About Us

Meidear is a global leader in PCB manufacturing, offering innovative and reliable solutions for a wide range of industries.

Core Manufacturing Capabilities & Quality Assurance

Comprehensive PCB Solutions: We specialize in high-quality, customized PCB manufacturing, including rigid, flexible, multilayer, and MCPCB, alongside PCB assembly and testing services.

Precision and Efficiency: Equipped with state-of-the-art facilities and automation systems, we guarantee precise and efficient production processes.

Certifications: We hold several industry-standard certifications, ensuring our products meet international quality and safety standards.

Quality Control: Our rigorous quality control system encompasses every stage, from design through to final product testing. This ensures all PCBs adhere to customer specifications and function optimally in their intended applications.

Proven Production Strength

Capacity and Speed: Our advanced automated production lines allow us to handle a range of orders, from small prototypes to large-volume productions. We offer rapid turnaround times with sample production within 3-5 days and mass production completed in as little as 3-5 days for standard boards.

Highly Skilled Workforce: Our experienced engineers and technicians ensure high-quality output, minimizing errors and maximizing reliability.

Customer-Centric Approach: We prioritize customer satisfaction, offering tailored solutions for diverse industry needs.

Sustainability Measures

Environmental Responsibility: We are committed to sustainability by using eco-friendly materials and efficient production practices. Our focus on reducing waste and energy consumption aligns with global sustainability goals.

Customer Collaboration Process

Clear Communication: From initial inquiry to final product delivery, we maintain transparent communication and provide dedicated support throughout the process.

Seamless Workflow: Our robust workflow ensures efficient project management, with clear timelines and quality assurance protocols at every stage.

Global Service Network

Worldwide Reach: With a strong logistics network and international shipping options, we deliver to customers across the globe. We work with clients from various regions, ensuring responsive and reliable service no matter the location.

Partner with Us for Your PCB Needs Ready to experience the Meidear advantage? Contact us today to learn more about how our advanced PCB solutions can power your next project.

FAQ

Who are we?

We are Meidear, a leading manufacturer specializing in high-quality printed circuit boards (PCBs) and advanced electronic solutions for a wide range of industries worldwide.

How can we guarantee quality?

We guarantee the quality of our products through stringent quality control measures, certified manufacturing processes, and comprehensive testing at every stage of production to ensure precision and reliability.

What can you buy from us?

We offer a variety of PCB products, including single-sided, multi-layer, flexible PCBs, MCPCBs, and other solutions like gold finger PCBs, LED PCBs, and HDI PCBs.

Why should you buy from us and not from other suppliers?

Our commitment to quality, fast lead times, and customer-focused service sets us apart. We offer customized solutions, flexible production capabilities, and competitive pricing, backed by strong global logistics and dedicated support.

What services can we provide?

In addition to PCB manufacturing, we offer PCB assembly, prototype services, design support, and logistics management. We ensure seamless project execution from initial consultation to final delivery.

Need durable and high-precision multilayer PCBs? Contact Meidear today for expert manufacturing solutions and fast, global delivery!