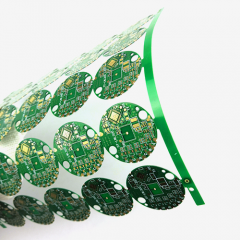

Extra Thin FR4 PCB

Extra Thin PCB Ultra-thin Printed Circuit Board

The standard thickness of a circuit board is currently 1.5mm.

The min-imum thickness is 0.2 mm for the majority of circuit boards.

With the market demand pushing for thinner devices,

there is a demand for min-thickness PCB boards such as 0.2 mm, 0.4

The min-imum thickness is 0.2 mm for the majority of circuit boards.

With the market demand pushing for thinner devices,

there is a demand for min-thickness PCB boards such as 0.2 mm, 0.4

Description

What's the extra thin or ultra-thin PCB?

The extra thin or ultra-thin printed circuit (usually thickness with 0.2mm) means the thickness of printed circuit board is more thin than standard PCB.There is a demand for min-imum thickness PCB boards such as 0.2 mm, 0.4 mm, 0.5 mm board, etc.

These are typically used in sensor cards, SIM cards, and so on.

Rigid board Ultra-thin base materials FR4

Normally, the standard thickness of a circuit board is currently 1.6mm.

For most of FR4 PCB, Min thickness is 0.3mm or 0.4mm, whatever it is 1L or 2L. For 4L, it will be more about 0.6mm.

For extra thin PCB, Meidear pcb can make it at 0.15mm, 0.20mm, 0.25mm, 0.30mm, with or without the soldermask, and copper thickness 1/2OZ, 1OZ.

At present, the 0.2mm Fr4 PCB can be said to be the thinnest. Because it is very thin and easily broken, the production process is more complicated, the yield is low, and the manufacturing cost is high. And the extremely thin PCB can limit the surface treatment operation.

In general, the standard gold immersion surface coating can support PCBs with a min thickness of 0.2mm, while HASL lead-free is only suitable for a min thickness of 0.6mm. The min thickness of immersion tin and silver is 0.4mm.

If there are no special production requirements, it is recommended that you replace the 0.2mm Fr4 Printed Circuit Board with Flex PCB. Because Flex PCB has a conventional thickness of 0.2mm, the thinnest can reach 0.1mm. It can fully meet the wiring production requirements of the double layers. From good frequency to production cost, Flex PCB is the best substitute.

If you need board thickness less than 0.10mm, then you should use flexible circuit which can be 0.06mm for 1L FPC or 0.10mm for 2L FPC.

| Extra Thin Board Capability Base material: FR4 Board Thickness: 0.1mm~0.3mm(+-0.03) Copper thickness: 0.5 OZ, 1.0 OZ Outline: Routing, punching, V-Cut Soldermask: Bare/White/Black/Blue/Green/Red Oil Legend/Silkscreen Color: Black/White Surface finishing: Immersion Gold, HASL, OSP Max Panel size: 600*500mm Packing: Vacuum Samples L/T: 7~9 Days MP L/T: 8~10 Days |

|

Flexible board Ultra-thin base materials PI

With flexible substrates, it is possible to create PCBs that fold to reduce the surface area and volume needed to house the PCB and thus increase the integration density. Using thinner flex materials rather than traditional thick FR4 materials can reduce the space needed for the PCB even more.

Extra Thin Flex Board Capability

Base material: PI

Board Thickness: 0.1mm~0.3mm

Copper thickness: 0.5 OZ, 1.0 OZ, 1.5 OZ, 2.0 OZ

Outline: Laser, punching

Coverlay: Bare/White/Black/Blue/Green/Red PI film

Legend/Silkscreen Color: Black/White

Surface finishing: Immersion Gold, OSP

Max Panel size: 1500*500mm

Packing: Vacuum

Samples L/T: 7~9 Days

MP L/T: 8~10 Days

Please contact us for more information about extra thin PCB.

mkt@me-pcb.com