Double Sided Flexible FPCB

Professional Manufacturing and SMT Assembly of Flexible LED Strips

Item No.: FPC04

Custom Production and SMT Processing for Flexible LED Light Bars

Two‑layer SMT flexible LED strip with 0.23 mm thickness, 35 µm copper, white solder mask, OSP finish; made by flexible printed circuit board experts and pcb suppliers for LED lighting.

Two‑layer SMT flexible LED strip with 0.23 mm thickness, 35 µm copper, white solder mask, OSP finish; made by flexible printed circuit board experts and pcb suppliers for LED lighting.

Description

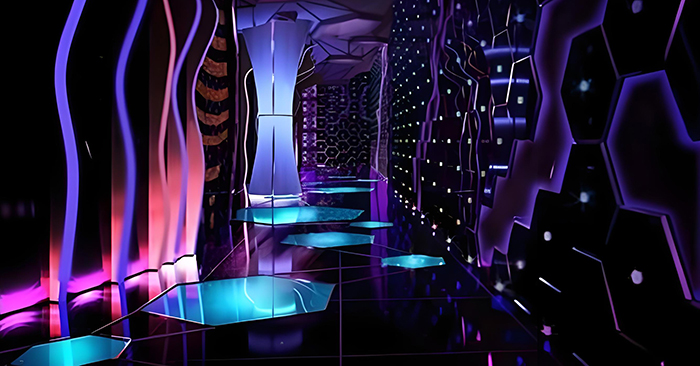

Nighttime display effects of the multi-color LED series

| Board name: | Multi-color LED series: nighttime visual effects |

| Overall dimensions of pannel: | 125*503/12pcs |

| Layer No. | 2L |

| Thermal conductivity: | No |

| Final board thickness: | 0.23mm |

| Copper thickness total: | 35um / 1Oz |

| Base material : | Flexible PCB |

| Solder mask color: | White |

| Silkscreen: | Black |

| Finishing: | OSP |

| Min hole: | 0.2mm |

| Bow&twist(IPC-TM-650): | 0.75% |

| Gerber data format: | Gerber RS-274X |

Professional Flexible LED Strip Manufacturing & SMT Assembly Services

Meidear pcb specialize in the custom production of high-quality flexible LED strips and precision SMT (Surface Mount Technology) assembly. Our end-to-end solutions cover:

LED PCB Fabrication: Flexible/Rigid-Flex boards with optimized thermal management.

SMT Processing: High-speed pick-and-place, solder paste printing, and reflow soldering for consistent component mounting.

Quality Focus: AOI (Automated Optical Inspection) and rigorous testing for brightness uniformity and reliability.

OEM/ODM Support: Tailored designs for decorative, architectural, or industrial lighting applications.

From prototyping to mass production, we ensure energy-efficient, durable LED strips with seamless SMT integration.

Customizable Highlights:

Add certifications: "RoHS/CE-compliant, IP65+ waterproof options available."

Detailed Physical and Material Specifications

This LED strip board is built on a flexible printed circuit board base material with two layers (2L). It has a final board thickness of 0.23 mm and uses total copper thickness of 35 µm (1 Oz). The solder mask is white with black silkscreen; finishing is OSP. The hole size can be as small as 0.2 mm. Panel dimensions are 125 × 503 mm per 12 pieces. The product is produced under Gerber RS‑274X data format; bow & twist (IPC‑TM‑650) is limited to 0.75%. These precise specifications support customers requiring consistency and accuracy, especially from pcb suppliers who demand repeatability and from pcb assembly supplier workflows.

Manufacturing Process and SMT Assembly Features

Meidear carries out SMT (Surface Mount Technology) assembly on this flexible LED strip board. Components are placed and soldered following industry established processes. The white mask aids visual inspection; black silkscreen aids component identification. Finishing by OSP provides solderability. As a pcb assembly supplier, Meidear handles both the board fabrication and the SMT assembly steps. The use of flexible circuit board material enables bending or adapting the board shape in LED strip applications without compromising electrical or mechanical integrity.

Quality Control and Compliance Details

Quality checks include the bow and twist test with a tolerance (IPC‑TM‑650) of 0.75%. Hole size down to 0.2 mm. The Gerber file standard (RS‑274X) ensures compatibility with common layout tools and manufacturing systems. There is no specific thermal conductivity value listed. For projects needing a flexible circuit board with reliable consistency, these specs provide transparency. Meidear’s role as pcb suppliers ensures that fabrication is done to these metrics in full, before proceeding to assembly or delivery.

Product Advantages

Thin Flexible Design for Space‑Constrained Lighting

At only 0.23 mm total thickness and built with two layers, this flexible printed circuit board permits installation in tight, curved, or compact lighting fixtures. Such slimness reduces weight and improves adaptability. These qualities are valuable to designers and manufacturers who rely on flexible circuit board solutions from capable pcb suppliers.

Consistent Copper Thickness and Board Integrity

With 35 µm copper (1 Oz), the board provides stable conductivity for LED strips without excessive heating or drop‑voltage issues. The white solder mask with black silkscreen ensures clarity in assembly and inspection. These parameters support the needs of a pcb assembly supplier process where accurate soldering and component placement are critical.

Reliable Manufacturing Standards and Traceability

The board is produced using Gerber RS‑274X files for layout accuracy, with min hole size 0.2 mm and bow & twist limited to 0.75% per IPC‑TM‑650. OSP finishing supports soldering consistency. These control points reflect Meidear’s capability both as pcb suppliers and a pcb assembly supplier, offering reliable product batches meeting project requirements.

About Us

ufacturing, offering innovative and reliable solutions for a wide range of industries.

Core Manufacturing Capabilities & Quality Assurance

Comprehensive PCB Solutions: We specialize in high-quality, customized PCB manufacturing, including rigid, flexible, multilayer, and MCPCB, alongside PCB assembly and testing services.

Precision and Efficiency: Equipped with state-of-the-art facilities and automation systems, we guarantee precise and efficient production processes.

Certifications: We hold several industry-standard certifications, ensuring our products meet international quality and safety standards.

Quality Control: Our rigorous quality control system encompasses every stage, from design through to final product testing. This ensures all PCBs adhere to customer specifications and function optimally in their intended applications.

Proven Production Strength

Capacity and Speed: Our advanced automated production lines allow us to handle a range of orders, from small prototypes to large-volume productions. We offer rapid turnaround times with sample production within 3-5 days and mass production completed in as little as 3-5 days for standard boards.

Highly Skilled Workforce: Our experienced engineers and technicians ensure high-quality output, reducing errors and enhancing reliability.

Customer-Centric Approach: We prioritize customer satisfaction, offering tailored solutions for diverse industry needs.

Sustainability Measures

Environmental Responsibility: We are committed to sustainability by using eco-friendly materials and efficient production practices. Our focus on reducing waste and energy consumption aligns with global sustainability goals.

Customer Collaboration Process

Clear Communication: From initial inquiry to final product delivery, we maintain transparent communication and provide dedicated support throughout the process.

Seamless Workflow: Our robust workflow ensures efficient project management, with clear timelines and quality assurance protocols at every stage.

Global Service Network

Worldwide Reach: With a strong logistics network and international shipping options, we deliver to customers across the globe. We work with clients from various regions, ensuring responsive and reliable service no matter the location.

Partner with Us for Your PCB Needs Ready to experience the Meidear advantage? Contact us today to learn more about how our advanced PCB solutions can power your next project.

FAQ

Who are we?

We are Meidear, a leading manufacturer specializing in high-quality printed circuit boards (PCBs) and advanced electronic solutions for a wide range of industries worldwide.

How can we guarantee quality?

We guarantee the quality of our products through stringent quality control measures, certified manufacturing processes, and comprehensive testing at every stage of production to ensure precision and reliability.

What can you buy from us?

We offer a variety of PCB products, including single-sided, multi-layer, flexible PCBs, MCPCBs, and other solutions like gold finger PCBs, LED PCBs, and HDI PCBs.

Why should you buy from us and not from other suppliers?

Our commitment to quality, fast lead times, and customer-focused service sets us apart. We offer customized solutions, flexible production capabilities, and competitive pricing, backed by strong global logistics and dedicated support.

What services can we provide?

In addition to PCB manufacturing, we offer PCB assembly, prototype services, design support, and logistics management. We ensure seamless project execution from initial consultation to final delivery.

Need high-performance flexible PCBs for your next project? Contact Meidear today for custom PCB printing and manufacturing services that exceed expectations!