Double Sided Flexible FPCB

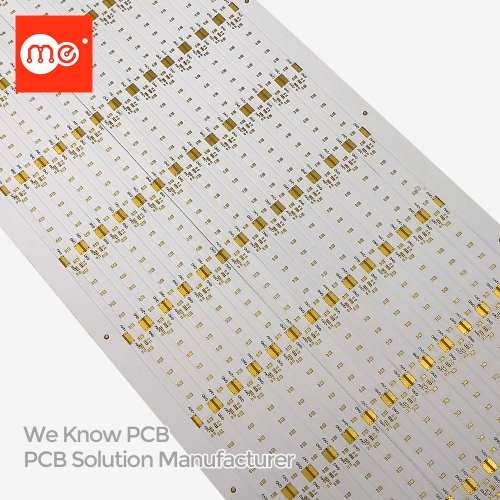

Flexible PCB for Strip Light

Flexible Copper Clad Laminate

Electro-Deposited copper

35um/70um

Surface Finishing: Immersion Gold 1u'

Electro-Deposited copper

35um/70um

Surface Finishing: Immersion Gold 1u'

Description

Customized flex PCB board, Flex pcb assembly, One stop FPC manufacturer OEM

Precision Built Double‑Sided Flex PCB Structure

This flex board is made from a flexible copper clad laminate, with copper thickness options of 35 µm or 70 µm, and plated with immersion gold at 1 µm. The double‑sided design provides conductive traces on both faces, allowing compact layouts. The flexible base material allows bending or shaping where rigid boards cannot fit. As one of the offerings by Meidear, this product shows their capability in flexible circuit board fabrication using standard electro‑deposited copper laminates and precise surface finishing. It integrates feature‑rich copper layers on both sides suited for strip lighting designs that require uniform current distribution and consistent conductivity.

Manufacturing Process and Customization Options

Meidear offers custom flex PCB board manufacturing for this strip light model. Customers can request tailor‑made dimensions, copper thickness, and surface finish to match application needs. The immersion gold (1 µm) finish gives surface protection and solderability. As a pcb assembly supplier, Meidear supports one‑stop OEM services including flex pcb assembly and fabrication. The company handles the full process from material selection (electro‑deposited copper) to finishing, implying quality control over flexible printed circuit board layout and assembly. The firm’s processes cover flexible board bending tolerances and ensure that copper weights and plating meet specified design standards.

Key Physical and Application‑Related Details

The board is specifically designed for strip light applications. Its flexible nature allows mounting along curves or edges in lighting products. The double‑sided copper enables routing and power delivery on both sides to support even LED distribution. Copper thickness (35 µm/70 µm) is chosen depending on current load; immersion gold finishing helps resist oxidation and supports solder connections. Meidear positions this strip‑light flex PCB under its Flex PCBs product category, alongside Single‑Sided Flexible PCB and Double‑Sided Flexible FPCB. Contact address is in Bao’an, Shenzhen, China. Electrical parameters beyond copper thickness and finishing are not listed.

Product Advantages

Enhanced Durability Through Copper Thickness and Finishing

Using 35 µm or 70 µm electro‑deposited copper provides robustness in current carrying and physical resilience. The immersion gold finish (1 µm) protects exposed copper surfaces against environmental degradation, facilitating solder joints and longevity. These features make the flexible printed circuit board more resistant to mechanical stress or handling, especially important where pcb assembly supplier quality is required.

Flexible Layout Capability for Complex Lighting Forms

Because the board is flexible and double‑sided, it can be bent or shaped to follow curves, edges, or confined spaces in lighting fixtures. This layout flexibility supports strip lighting systems needing continuous light along non‑linear paths. The board’s double‑side copper routing enables more efficient trace routing without requiring large planar area. As a flexible circuit board product, it allows designers more freedom than rigid boards.

OEM‑Level Customization and Integration Support

Meidear provides custom OEM fabrication and assembly: customers can order tailored copper thickness (35/70 µm), choose surface finish (immersion gold), and supply layouts for double‑sided flex boards. Being also a pcb assembly supplier, the company offers one‑stop service, which reduces coordination overhead and ensures consistent quality across design, fabrication, and finishing. That integration helps clients who need both board manufacture and assembly under one roof.

Use Scenarios

LED Strip Lighting Installations in Architectural Fixtures

In architectural lighting where strip lights run along curved ceilings, coves, or facades, the flexibility of this printed circuit board allows conformal mounting. Designers can shape the board to match curves, and the double‑sided copper ensures the necessary current delivery. Meidear’s offering as a pcb suppliers source supports components integrating with LED modules in such lighting systems.

Retrofit and Custom Lighting Panels or Signage

For custom signage or panels that require lighting in non‑standard shapes—e.g. illuminated signs or light boxes—the strip light flex PCB can be fitted to backing surfaces or frames that are not flat. The customized copper thickness lets the client handle power distribution; the immersion gold finish helps with soldering LEDs or connectors. As a pcb assembly supplier, Meidear supports clients needing both board supply and assembly.

Industrial or Commercial Lighting Solutions with Tailored Layouts

Factories, showrooms, or commercial displays sometimes require lighting that follows machinery contours, staircases, display stands. In such settings, precise layouts and durability matter. Using a double‑sided flexible circuit board from Meidear ensures the required shape is possible and that current path integrity is maintained. Those seeking reliable pcb layout services will benefit particularly in this scenario.

About Us

Meidear PCB (often branded “MePCb”) is a Shenzhen, China‑based electronics manufacturer specializing in printed circuit board fabrication and assembly. Established in 2014, the company designs and produces a range of PCBs including rigid, flex, rigid‑flex, HDI, heavy copper, MCPCB, and other special types.

The firm’s core market includes OEMs requiring flexible printed circuit board solutions, LED lighting applications (including strip lights), industrial electronics, telecom, medical devices, and other sectors seeking custom PCB fabrication. Meidear also provides pcb assembly supplier services, meaning they handle both bare board fabrication and assembly when required.

Manufacturing capacity includes copper thickness options (e.g. 35 µm & 70 µm) for flex copper clad laminates, use of immersion gold surface finishing (1 µm), and the infrastructural capabilities to support flexible circuit board design, copper plating, and finishing. They maintain quality via standardized processes, with flexible circuit board technology among their technical capabilities.

FAQ

What copper thickness options are available for this product?

Meidear offers electro‑deposited copper in 35 µm and 70 µm thicknesses for the flexible printed circuit board used in the strip light design.

What surface finish is used on the flexible PCB?

The product uses an immersion gold finish of 1 µm on its exposed copper surfaces.

Does Meidear sell both single‑sided and double‑sided flex PCBs?

Yes. The company offers both Single Sided Flexible PCB and Double Sided Flexible FPCB in its Flex PCBs product category.

Can Meidear handle PCB assembly in addition to supplying bare boards?

Yes. Meidear provides pcb assembly supplier services, offering one‑stop OEM flex pcb assembly as well as the fabrication of bare flexible circuit board products.

Where is Meidear located and how can someone contact them?

Meidear is located in Bao’an, Shenzhen, China at “Huahaogaoxin Bg xinqiao street, Bao’an, Shenzhen, China”. Contact phone is +86‑755‑23008682, and email is mkt@me‑pcb.com.

Request your custom strip light flex PCB from Meidear now if you're a lighting OEM ready to integrate flexible circuit board!

Precision Built Double‑Sided Flex PCB Structure

This flex board is made from a flexible copper clad laminate, with copper thickness options of 35 µm or 70 µm, and plated with immersion gold at 1 µm. The double‑sided design provides conductive traces on both faces, allowing compact layouts. The flexible base material allows bending or shaping where rigid boards cannot fit. As one of the offerings by Meidear, this product shows their capability in flexible circuit board fabrication using standard electro‑deposited copper laminates and precise surface finishing. It integrates feature‑rich copper layers on both sides suited for strip lighting designs that require uniform current distribution and consistent conductivity.

Manufacturing Process and Customization Options

Meidear offers custom flex PCB board manufacturing for this strip light model. Customers can request tailor‑made dimensions, copper thickness, and surface finish to match application needs. The immersion gold (1 µm) finish gives surface protection and solderability. As a pcb assembly supplier, Meidear supports one‑stop OEM services including flex pcb assembly and fabrication. The company handles the full process from material selection (electro‑deposited copper) to finishing, implying quality control over flexible printed circuit board layout and assembly. The firm’s processes cover flexible board bending tolerances and ensure that copper weights and plating meet specified design standards.

Key Physical and Application‑Related Details

The board is specifically designed for strip light applications. Its flexible nature allows mounting along curves or edges in lighting products. The double‑sided copper enables routing and power delivery on both sides to support even LED distribution. Copper thickness (35 µm/70 µm) is chosen depending on current load; immersion gold finishing helps resist oxidation and supports solder connections. Meidear positions this strip‑light flex PCB under its Flex PCBs product category, alongside Single‑Sided Flexible PCB and Double‑Sided Flexible FPCB. Contact address is in Bao’an, Shenzhen, China. Electrical parameters beyond copper thickness and finishing are not listed.

Product Advantages

Enhanced Durability Through Copper Thickness and Finishing

Using 35 µm or 70 µm electro‑deposited copper provides robustness in current carrying and physical resilience. The immersion gold finish (1 µm) protects exposed copper surfaces against environmental degradation, facilitating solder joints and longevity. These features make the flexible printed circuit board more resistant to mechanical stress or handling, especially important where pcb assembly supplier quality is required.

Flexible Layout Capability for Complex Lighting Forms

Because the board is flexible and double‑sided, it can be bent or shaped to follow curves, edges, or confined spaces in lighting fixtures. This layout flexibility supports strip lighting systems needing continuous light along non‑linear paths. The board’s double‑side copper routing enables more efficient trace routing without requiring large planar area. As a flexible circuit board product, it allows designers more freedom than rigid boards.

OEM‑Level Customization and Integration Support

Meidear provides custom OEM fabrication and assembly: customers can order tailored copper thickness (35/70 µm), choose surface finish (immersion gold), and supply layouts for double‑sided flex boards. Being also a pcb assembly supplier, the company offers one‑stop service, which reduces coordination overhead and ensures consistent quality across design, fabrication, and finishing. That integration helps clients who need both board manufacture and assembly under one roof.

Use Scenarios

LED Strip Lighting Installations in Architectural Fixtures

In architectural lighting where strip lights run along curved ceilings, coves, or facades, the flexibility of this printed circuit board allows conformal mounting. Designers can shape the board to match curves, and the double‑sided copper ensures the necessary current delivery. Meidear’s offering as a pcb suppliers source supports components integrating with LED modules in such lighting systems.

Retrofit and Custom Lighting Panels or Signage

For custom signage or panels that require lighting in non‑standard shapes—e.g. illuminated signs or light boxes—the strip light flex PCB can be fitted to backing surfaces or frames that are not flat. The customized copper thickness lets the client handle power distribution; the immersion gold finish helps with soldering LEDs or connectors. As a pcb assembly supplier, Meidear supports clients needing both board supply and assembly.

Industrial or Commercial Lighting Solutions with Tailored Layouts

Factories, showrooms, or commercial displays sometimes require lighting that follows machinery contours, staircases, display stands. In such settings, precise layouts and durability matter. Using a double‑sided flexible circuit board from Meidear ensures the required shape is possible and that current path integrity is maintained. Those seeking reliable pcb layout services will benefit particularly in this scenario.

About Us

Meidear PCB (often branded “MePCb”) is a Shenzhen, China‑based electronics manufacturer specializing in printed circuit board fabrication and assembly. Established in 2014, the company designs and produces a range of PCBs including rigid, flex, rigid‑flex, HDI, heavy copper, MCPCB, and other special types.

The firm’s core market includes OEMs requiring flexible printed circuit board solutions, LED lighting applications (including strip lights), industrial electronics, telecom, medical devices, and other sectors seeking custom PCB fabrication. Meidear also provides pcb assembly supplier services, meaning they handle both bare board fabrication and assembly when required.

Manufacturing capacity includes copper thickness options (e.g. 35 µm & 70 µm) for flex copper clad laminates, use of immersion gold surface finishing (1 µm), and the infrastructural capabilities to support flexible circuit board design, copper plating, and finishing. They maintain quality via standardized processes, with flexible circuit board technology among their technical capabilities.

FAQ

What copper thickness options are available for this product?

Meidear offers electro‑deposited copper in 35 µm and 70 µm thicknesses for the flexible printed circuit board used in the strip light design.

What surface finish is used on the flexible PCB?

The product uses an immersion gold finish of 1 µm on its exposed copper surfaces.

Does Meidear sell both single‑sided and double‑sided flex PCBs?

Yes. The company offers both Single Sided Flexible PCB and Double Sided Flexible FPCB in its Flex PCBs product category.

Can Meidear handle PCB assembly in addition to supplying bare boards?

Yes. Meidear provides pcb assembly supplier services, offering one‑stop OEM flex pcb assembly as well as the fabrication of bare flexible circuit board products.

Where is Meidear located and how can someone contact them?

Meidear is located in Bao’an, Shenzhen, China at “Huahaogaoxin Bg xinqiao street, Bao’an, Shenzhen, China”. Contact phone is +86‑755‑23008682, and email is mkt@me‑pcb.com.

Request your custom strip light flex PCB from Meidear now if you're a lighting OEM ready to integrate flexible circuit board!