FPCB Yellow film

Item No.: F000130

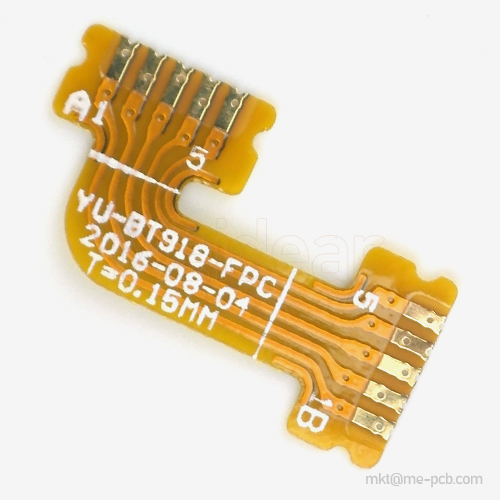

Single-layer flexible printed circuit board with yellow film surface for clear trace visibility and durable protection, fabricated by pcb suppliers with precision lamination technology.

Description

Distinctive Surface Treatment for Visual Differentiation

This product features a yellow cover film bonded to the surface of a single-layer flexible circuit, offering distinctive appearance and trace protection. The film enhances visual contrast between the insulating material and exposed copper features, improving inspection accuracy. The clean presentation of trace outlines and pad geometry also reduces visual fatigue during manual handling. As part of Meidear’s flexible PCB line, this film-coated flexible printed circuit board provides a reliable structure for systems requiring consistent pad location and visual identification. As one of the established pcb suppliers, Meidear ensures consistency in color tone, material transparency, and adhesion properties across every batch.

Durable Laminate Structure with Pad Window Precision

This FPC is manufactured using a consistent lamination process that integrates the yellow film with the circuit base. The laminated film features pre-cut windows to expose soldering pads, leaving the rest of the circuit protected. Each film layer is aligned to match pad locations exactly, reducing the risk of soldering errors or misaligned contact points. Meidear controls lamination pressure and alignment to maintain pad accuracy and trace insulation. Clients submitting files for this format receive feedback as part of Meidear’s pcb layout services, ensuring their designs are optimized for coverlay processing. The resulting flexible circuit board meets both physical alignment and surface insulation requirements without additional processing.

Streamlined Format for Standard Connector Matching

The board uses a flat, single-conductor design with no internal layers, suited for applications needing low-profile circuit paths and straightforward pad placement. The exposed areas on the yellow film are spaced and dimensioned for compatibility with standard connectors or edge contacts. This structural simplicity allows fast placement and soldering, especially in applications relying on manual attachment or basic assembly lines. As a pcb assembly supplier, Meidear applies stable punching and cutting processes to ensure every circuit matches its layout reference exactly. This layout-to-production continuity makes the board easy to integrate and dependable during assembly and testing.

Product Advantages

High Contrast Surface for Visual Identification

The yellow cover film not only adds physical protection to the base material but also enhances contrast for easy visual assessment. Compared to transparent or darker films, yellow offers better readability of trace paths and soldering points. This is especially valuable during quality checks or manual installation. Meidear applies calibrated film tension and color stability control throughout its process, making each flexible printed circuit board uniform in tone and visibility. For teams handling multiple variants or color-coded layouts, this visual consistency aids quick identification and sorting—advantages often sought when choosing experienced pcb suppliers.

Reliable Trace Protection and Pad Exposure Balance

While exposing only the necessary solder pads, the film shields adjacent traces and inactive areas from dust, scratches, and accidental bridging. The pre-punched pad windows are defined by Meidear’s process tools, avoiding irregular edges or misalignment. As a pcb assembly supplier, Meidear ensures the balance between pad accessibility and trace coverage remains stable throughout the run. Whether applied in sample orders or larger batches, the film does not delaminate or wrinkle, helping the board retain its intended profile and insulating characteristics in real-world environments.

Consistency in Layer Clarity and Edge Control

Each unit maintains a fixed outline and uniform film application, allowing confident integration into modular or size-sensitive applications. Whether routed manually or automatically, the board aligns easily with assembly fixtures due to the repeatable contour and predictable pad locations. The yellow film’s transparency is tuned to support visibility while resisting warping. Clients who require specific edge formats or layout modifications benefit from Meidear’s pcb layout services, which support file pre-checks and tooling adaptations. These precision methods ensure the flexible circuit board maintains its designed dimensions, film clarity, and integration readiness at all production scales.

Use Scenarios

Color-Coded Boards for Production Line Sorting

The yellow surface color enables quick visual identification, useful in environments where multiple FPC designs are handled simultaneously. Production teams can distinguish between versions of a board at a glance without scanning serial numbers. The film finish resists smudging and peeling, making it reliable for repeated handling. This application scenario is supported by Meidear’s role as a trusted pcb suppliers provider, offering color-coded circuit options for clients who prioritize visual workflow efficiency when managing flexible printed circuit board batches.

Connector-Based Devices Requiring Flat Pad Geometry

The clear pad layout exposed through the yellow film is ideal for devices where connectors must attach to flat terminal points. This includes signal interfaces, plug-in units, or adapter boards with repeatable connection cycles. The uniform yellow film prevents pad misreading during alignment, improving solder joint accuracy. Meidear supports such projects through its role as a pcb assembly supplier, offering tight pad dimensional control and board surface integrity that aid assembly workers during installation.

Low-Complexity Interconnects with Visibility Focus

In applications where only basic signal transmission is required—without multi-layer routing or embedded components—this yellow-film single-layer FPC provides a clean, effective solution. Its simplicity does not compromise on inspection or assembly speed, especially when visual referencing is necessary. Ideal for education, testing, or pre-production systems, the board allows engineers and testers to trace signals easily. Meidear’s pcb layout services team supports iterative improvement cycles based on real-time layout feedback, making this flexible circuit board configuration practical for visibility-first applications.

About Us

Founded in 2014, Shenzhen Meidear Co., Limited operates as a full-service manufacturer of printed circuit boards and assemblies. The company specializes in flexible circuit board production, including single-layer, multi-layer, rigid-flex, and coverlay-treated formats. Its capabilities extend across industries such as lighting, industrial control, and modular electronics. Meidear provides in-house pcb layout services, accepting standard design formats such as CAM350 and Protel, and supports file inspection before manufacturing. With no fixed order volume and support for rapid sampling, the company offers flexibility to clients ranging from early-stage developers to system integrators. As a recognized pcb assembly supplier, Meidear also handles post-fabrication tasks such as surface finishing, pad inspection, and global logistics. Its streamlined structure enables fast lead times, material traceability, and high-volume consistency.

FAQ

Does the yellow film cover the entire surface of the board?

Yes, the yellow film covers the surface except for pre-cut pad openings, offering full trace protection while maintaining pad accessibility on the flexible circuit board.

Is this a multilayer design?

No, this is a single-layer flexible printed circuit board with one conductor layer and yellow coverlay on top.

Can I submit my Gerber file for this product?

Yes, Meidear supports Gerber as well as CAM350 and Protel files through its pcb layout services team.

Are small batch orders accepted?

Yes, Meidear supports low-volume and sample orders with no MOQ, a standard offering among flexible pcb suppliers.

What packaging and shipping options are available?

Orders can be shipped globally using DHL, UPS, FedEx, or your preferred forwarder, organized by Meidear’s logistics and pcb assembly supplier services.

Send your yellow film circuit files to Meidear and receive a consistent, production-ready flexible circuit board from a trusted pcb suppliers partner!

This product features a yellow cover film bonded to the surface of a single-layer flexible circuit, offering distinctive appearance and trace protection. The film enhances visual contrast between the insulating material and exposed copper features, improving inspection accuracy. The clean presentation of trace outlines and pad geometry also reduces visual fatigue during manual handling. As part of Meidear’s flexible PCB line, this film-coated flexible printed circuit board provides a reliable structure for systems requiring consistent pad location and visual identification. As one of the established pcb suppliers, Meidear ensures consistency in color tone, material transparency, and adhesion properties across every batch.

Durable Laminate Structure with Pad Window Precision

This FPC is manufactured using a consistent lamination process that integrates the yellow film with the circuit base. The laminated film features pre-cut windows to expose soldering pads, leaving the rest of the circuit protected. Each film layer is aligned to match pad locations exactly, reducing the risk of soldering errors or misaligned contact points. Meidear controls lamination pressure and alignment to maintain pad accuracy and trace insulation. Clients submitting files for this format receive feedback as part of Meidear’s pcb layout services, ensuring their designs are optimized for coverlay processing. The resulting flexible circuit board meets both physical alignment and surface insulation requirements without additional processing.

Streamlined Format for Standard Connector Matching

The board uses a flat, single-conductor design with no internal layers, suited for applications needing low-profile circuit paths and straightforward pad placement. The exposed areas on the yellow film are spaced and dimensioned for compatibility with standard connectors or edge contacts. This structural simplicity allows fast placement and soldering, especially in applications relying on manual attachment or basic assembly lines. As a pcb assembly supplier, Meidear applies stable punching and cutting processes to ensure every circuit matches its layout reference exactly. This layout-to-production continuity makes the board easy to integrate and dependable during assembly and testing.

Product Advantages

High Contrast Surface for Visual Identification

The yellow cover film not only adds physical protection to the base material but also enhances contrast for easy visual assessment. Compared to transparent or darker films, yellow offers better readability of trace paths and soldering points. This is especially valuable during quality checks or manual installation. Meidear applies calibrated film tension and color stability control throughout its process, making each flexible printed circuit board uniform in tone and visibility. For teams handling multiple variants or color-coded layouts, this visual consistency aids quick identification and sorting—advantages often sought when choosing experienced pcb suppliers.

Reliable Trace Protection and Pad Exposure Balance

While exposing only the necessary solder pads, the film shields adjacent traces and inactive areas from dust, scratches, and accidental bridging. The pre-punched pad windows are defined by Meidear’s process tools, avoiding irregular edges or misalignment. As a pcb assembly supplier, Meidear ensures the balance between pad accessibility and trace coverage remains stable throughout the run. Whether applied in sample orders or larger batches, the film does not delaminate or wrinkle, helping the board retain its intended profile and insulating characteristics in real-world environments.

Consistency in Layer Clarity and Edge Control

Each unit maintains a fixed outline and uniform film application, allowing confident integration into modular or size-sensitive applications. Whether routed manually or automatically, the board aligns easily with assembly fixtures due to the repeatable contour and predictable pad locations. The yellow film’s transparency is tuned to support visibility while resisting warping. Clients who require specific edge formats or layout modifications benefit from Meidear’s pcb layout services, which support file pre-checks and tooling adaptations. These precision methods ensure the flexible circuit board maintains its designed dimensions, film clarity, and integration readiness at all production scales.

Use Scenarios

Color-Coded Boards for Production Line Sorting

The yellow surface color enables quick visual identification, useful in environments where multiple FPC designs are handled simultaneously. Production teams can distinguish between versions of a board at a glance without scanning serial numbers. The film finish resists smudging and peeling, making it reliable for repeated handling. This application scenario is supported by Meidear’s role as a trusted pcb suppliers provider, offering color-coded circuit options for clients who prioritize visual workflow efficiency when managing flexible printed circuit board batches.

Connector-Based Devices Requiring Flat Pad Geometry

The clear pad layout exposed through the yellow film is ideal for devices where connectors must attach to flat terminal points. This includes signal interfaces, plug-in units, or adapter boards with repeatable connection cycles. The uniform yellow film prevents pad misreading during alignment, improving solder joint accuracy. Meidear supports such projects through its role as a pcb assembly supplier, offering tight pad dimensional control and board surface integrity that aid assembly workers during installation.

Low-Complexity Interconnects with Visibility Focus

In applications where only basic signal transmission is required—without multi-layer routing or embedded components—this yellow-film single-layer FPC provides a clean, effective solution. Its simplicity does not compromise on inspection or assembly speed, especially when visual referencing is necessary. Ideal for education, testing, or pre-production systems, the board allows engineers and testers to trace signals easily. Meidear’s pcb layout services team supports iterative improvement cycles based on real-time layout feedback, making this flexible circuit board configuration practical for visibility-first applications.

About Us

Founded in 2014, Shenzhen Meidear Co., Limited operates as a full-service manufacturer of printed circuit boards and assemblies. The company specializes in flexible circuit board production, including single-layer, multi-layer, rigid-flex, and coverlay-treated formats. Its capabilities extend across industries such as lighting, industrial control, and modular electronics. Meidear provides in-house pcb layout services, accepting standard design formats such as CAM350 and Protel, and supports file inspection before manufacturing. With no fixed order volume and support for rapid sampling, the company offers flexibility to clients ranging from early-stage developers to system integrators. As a recognized pcb assembly supplier, Meidear also handles post-fabrication tasks such as surface finishing, pad inspection, and global logistics. Its streamlined structure enables fast lead times, material traceability, and high-volume consistency.

FAQ

Does the yellow film cover the entire surface of the board?

Yes, the yellow film covers the surface except for pre-cut pad openings, offering full trace protection while maintaining pad accessibility on the flexible circuit board.

Is this a multilayer design?

No, this is a single-layer flexible printed circuit board with one conductor layer and yellow coverlay on top.

Can I submit my Gerber file for this product?

Yes, Meidear supports Gerber as well as CAM350 and Protel files through its pcb layout services team.

Are small batch orders accepted?

Yes, Meidear supports low-volume and sample orders with no MOQ, a standard offering among flexible pcb suppliers.

What packaging and shipping options are available?

Orders can be shipped globally using DHL, UPS, FedEx, or your preferred forwarder, organized by Meidear’s logistics and pcb assembly supplier services.

Send your yellow film circuit files to Meidear and receive a consistent, production-ready flexible circuit board from a trusted pcb suppliers partner!