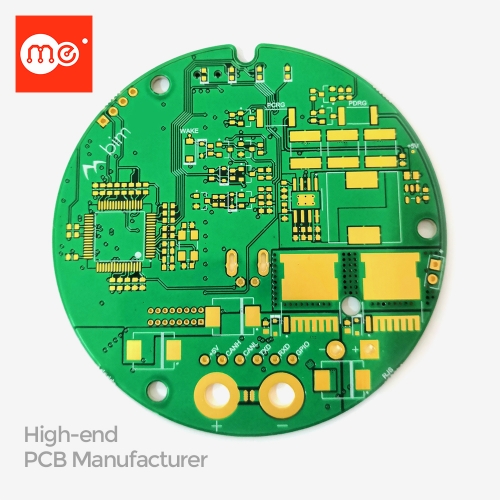

Multilayer PCB

FR4 high-end Immersion gold 3U

FR-4 4L Green SolderMask White Legend EING

4-layer FR4 Tg150 board with 1.6mm thickness, 0.2mm min hole, green solder mask, white silkscreen, and immersion gold surface; ideal for flex board PCB and precision PCB layout services.

4-layer FR4 Tg150 board with 1.6mm thickness, 0.2mm min hole, green solder mask, white silkscreen, and immersion gold surface; ideal for flex board PCB and precision PCB layout services.

Description

| Board name: | High-end FR-4 PCB |

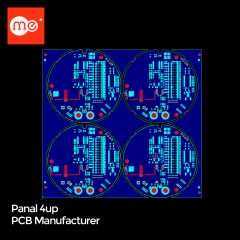

| Overall dimensions of pannel: | 152x142mm/4up |

| Layer No. | 4L |

| Thermal conductivity: | No |

| Final board thickness: | 1.6mm |

| Inner Copper thickness total: | 35um |

| Base material : | FR4 tg150 |

| Solder mask color: | Green |

| Silkscreen: | White |

| Finishing: | Immersion gold (EING) |

| Min hole: | 0.2mm |

| Bow&twist(IPC-TM-650): | 0.75% |

| Gerber data format: | Gerber RS-274X |

Material and Structural Specifications

This 4-layer PCB uses FR4 Tg150 material for thermal stability and mechanical strength, with 1.6mm finished thickness and 35µm copper, offering solid electrical paths and reliability. Featuring a green solder mask, white silkscreen, and a via hole size as small as 0.2mm, the board supports high-density interconnect layouts. The immersion gold surface enhances solderability and oxidation resistance, making it suitable for fine-pitch component designs. Warpage is controlled within IPC-TM-650 standards (≤0.75%), meeting requirements of precision PCB layout services and light flex board PCB applications.

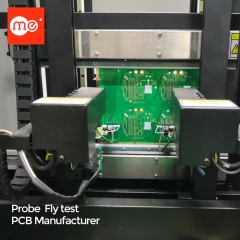

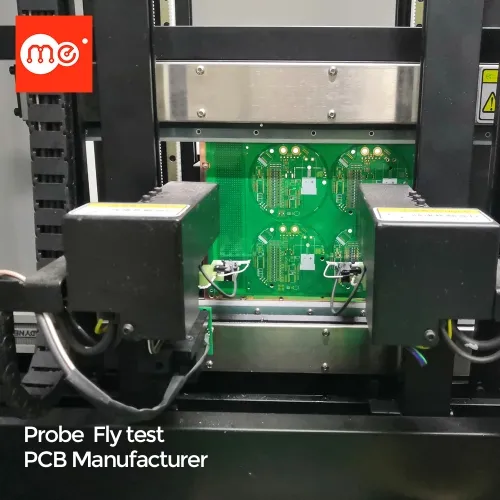

Manufacturing Process and Quality Control

Using Gerber RS-274X design files, the board undergoes multi-layer lamination, mechanical drilling, copper plating, and immersion gold surface treatment to deliver consistent solder performance. Each unit includes green solder mask and white legends, verified by electrical testing, dimensional inspection, and warpage measurement. The 152×142mm 4-up panel configuration enables efficient production runs for both prototyping and small batch orders, making it suitable for customers working with PCB manufacturers or PCB maker online services.

Target Applications and User Profiles

This product serves design engineers and industrial OEMs in fields like LED systems and automation, where stable multilayer designs are needed. Its 4-layer stackup accommodates power and ground planes, and its immersion gold finish offers long-term solder joint reliability. Users involved in online prototyping, precision routing, or flexible-fit installations will benefit from the board’s balance of mechanical rigidity and layout flexibility, making it ideal for both standard and semi-flexible PCB board design requirements.

Product Advantages

The immersion gold surface finish ensures flat, oxidation-resistant contact pads, significantly improving solderability for fine-pitch and BGA components. The nickel-gold plating system supports long-term durability, precise stencil printing, and strong joint formation under repeated reflow cycles. This makes it especially effective for flexible circuit board designs or high-reliability industrial assemblies requiring low defect rates and clean pad geometry under automated soldering workflows.

2. Precision Engineering with Tight Tolerances

Designed with via holes as small as 0.2mm, 35µm copper thickness, and IPC-standard flatness control, this board meets the technical needs of advanced PCB layout services. These tolerances enable confident placement of dense SMD components, high-speed signal lines, and embedded via structures. Whether through PCB manufacturer partners or online ordering platforms, engineers gain repeatability and performance assurance across production runs.

3. Layer Stackup Suitable for Ground and Signal Integrity

The 4-layer FR4 stackup with controlled thickness and dielectric properties supports stable ground and power planes, minimizing EMI and improving signal integrity. The immersion gold surface further ensures consistent impedance and high-quality solder joints across thermal cycles. Ideal for LED drivers and control systems, the board performs well in designs where PCB board design accuracy and material durability are key to long-term application success.

Use Scenarios

Industrial Environments

In factory environments like LED production or instrumentation assembly, this PCB's FR4 Tg150 base and immersion gold finish resist moisture, oxidation, and heat variation. The green solder mask withstands reflow and cleaning processes, while the white silkscreen remains legible. Its mild flexibility also suits fixed-position or semi-bend applications, aligning with mechanical and environmental needs of flex board PCB deployment.

Design-to-Manufacture Workflow

From file submission to board shipment, the process includes lamination, drilling, plating, gold finishing, and visual/electrical testing. With Gerber RS-274X input and defined copper, hole, and finish specs, the board transitions smoothly from prototype to small-volume runs. This supports efficient ordering through PCB maker online platforms, reducing design iteration and improving time-to-market for hardware teams using professional PCB layout services.

Functional Value in Application

For applications needing reliable signal transfer, repeat soldering, or compact stacking, this board delivers performance with cost-efficiency. Though not a flexible circuit board, it supports moderate mechanical stress and is suitable for LED drivers, industrial controls, and mid-speed digital routing. Its material and finish choices ensure long-term usage and compatibility with soldering processes, satisfying both OEM buyers and PCB manufacturers seeking durable solutions.

About Us

Meidear is a global leader in PCB manufacturing, offering innovative and reliable solutions for a wide range of industries.

Core Manufacturing Capabilities & Quality Assurance

Comprehensive PCB Solutions: We specialize in high-quality, customized PCB manufacturing, including rigid, flexible, multilayer, and MCPCB, alongside PCB assembly and testing services.

Precision and Efficiency: Equipped with state-of-the-art facilities and automation systems, we guarantee precise and efficient production processes.

Certifications: We hold several industry-standard certifications, ensuring our products meet international quality and safety standards.

Quality Control: Our rigorous quality control system encompasses every stage, from design through to final product testing. This ensures all PCBs adhere to customer specifications and function optimally in their intended applications.

Proven Production Strength

Capacity and Speed: Our advanced automated production lines allow us to handle a range of orders, from small prototypes to large-volume productions. We offer rapid turnaround times with sample production within 3-5 days and mass production completed in as little as 3-5 days for standard boards.

Highly Skilled Workforce: Our experienced engineers and technicians ensure high-quality output, minimizing errors and maximizing reliability.

Customer-Centric Approach: We prioritize customer satisfaction, offering tailored solutions for diverse industry needs.

Sustainability Measures

Environmental Responsibility: We are committed to sustainability by using eco-friendly materials and efficient production practices. Our focus on reducing waste and energy consumption aligns with global sustainability goals.

Customer Collaboration Process

Clear Communication: From initial inquiry to final product delivery, we maintain transparent communication and provide dedicated support throughout the process.

Seamless Workflow: Our robust workflow ensures efficient project management, with clear timelines and quality assurance protocols at every stage.

Global Service Network

Worldwide Reach: With a strong logistics network and international shipping options, we deliver to customers across the globe. We work with clients from various regions, ensuring responsive and reliable service no matter the location.

Partner with Us for Your PCB Needs Ready to experience the Meidear advantage? Contact us today to learn more about how our advanced PCB solutions can power your next project.

FAQ

Who are we?

We are Meidear, a leading manufacturer specializing in high-quality printed circuit boards (PCBs) and advanced electronic solutions for a wide range of industries worldwide.

How can we guarantee quality?

We guarantee the quality of our products through stringent quality control measures, certified manufacturing processes, and comprehensive testing at every stage of production to ensure precision and reliability.

What can you buy from us?

We offer a variety of PCB products, including single-sided, multi-layer, flexible PCBs, MCPCBs, and other solutions like gold finger PCBs, LED PCBs, and HDI PCBs.

Why should you buy from us and not from other suppliers?

Our commitment to quality, fast lead times, and customer-focused service sets us apart. We offer customized solutions, flexible production capabilities, and competitive pricing, backed by strong global logistics and dedicated support.

What services can we provide?

In addition to PCB manufacturing, we offer PCB assembly, prototype services, design support, and logistics management. We ensure seamless project execution from initial consultation to final delivery.

Need high-quality multilayer PCBs for your next project? Contact Meidear now for expert PCB manufacturing and fast, global delivery!