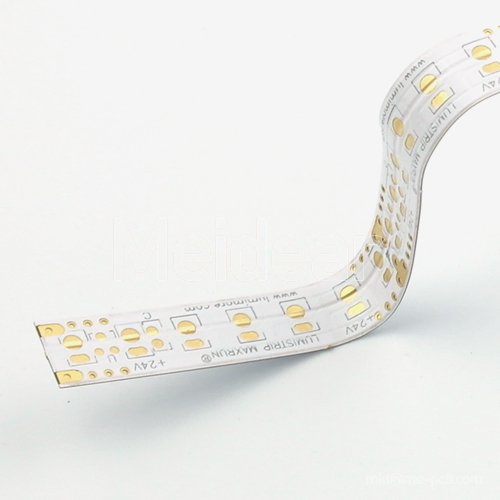

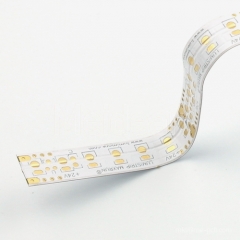

Heavy copper 3Oz Flexible Printed Circuit

Item No.: F000132

Heavy copper 3Oz Flexible Printed Circuit providing robust current capacity and durability, designed for demanding pcb layout services and precision pcb maker online supply chains.

Description

Material Composition and Physical Properties

This heavy copper flexible circuit board is built using approximately 3oz of copper per square foot, significantly increasing its durability and current-handling capability. It uses a flexible base material capable of enduring repeated bends without delamination. The thick copper layer enhances the mechanical resilience of the flex pcb while maintaining a consistent structure through layered insulation. At each stage of production—from copper lamination to coverlay application—careful process control ensures that the resulting pcb board design meets both mechanical and electrical requirements. With optimized trace width, spacing, and soldering pads, the product provides excellent structural integrity. These features are essential for clients working with pcb layout services or sourcing reliable designs from experienced pcb manufacturers aiming for high-current applications.

Electrical Performance and Thermal Reliability

The 3oz copper layer allows this flex pcb to carry higher currents with reduced resistive loss, making it ideal for systems that require efficient power delivery over bendable substrates. The increased copper cross-section reduces heat buildup, while the flexible polyimide substrate maintains thermal stability. The layered construction ensures electrical isolation and high voltage resistance, making this a dependable choice for mission-critical applications. For engineers working on power systems or complex devices requiring thermal resilience, this product delivers the structural and electrical consistency they expect from high-end flex board pcb solutions. It also allows precise customization, making it suitable for advanced pcb layout services and tailored builds by capable pcb manufacturers.

Manufacturing Process and Quality Control

Producing a 3oz heavy copper flexible circuit board demands advanced techniques to ensure clean etching, stable layering, and optimal flexibility. Meidear uses high-quality copper foil, chemical etching, and multi-stage lamination to construct circuits that meet strict tolerance standards. Post-fabrication, each board undergoes electrical testing, visual inspection, and bend-cycle stress validation to confirm durability. The entire process aligns with the expectations of professional pcb manufacturers and clients who rely on pcb maker online systems for both prototyping and scaled production. From layout verification to final delivery, the board reflects the required performance standards of modern pcb board design workflows.

Product Advantages

High Current Transmission with Structural Stability

This heavy copper flex pcb delivers enhanced current-carrying capability due to its ~3oz copper structure. Traces are optimized to reduce resistance and voltage drop under load, making the product ideal for power-intensive systems. It withstands sustained current flow without thermal degradation, thanks to its high-conductivity copper paths and reinforced insulation layers. The high current density support, combined with mechanical flexibility, gives engineers a rare combination of strength and form factor efficiency. These benefits are directly relevant to industrial pcb layout services and OEMs seeking high-load flex board pcb options manufactured by reliable pcb manufacturers.

Fatigue Resistance in Dynamic Applications

The increased copper thickness, when paired with flexible substrates and properly engineered bend zones, reduces the risk of cracking and electrical failure during repeated flexing. Meidear reinforces connection points and soldering pads, ensuring secure mechanical stability even under vibration or stress. The mechanical fatigue resistance adds measurable longevity to the overall system. Designers sourcing through pcb maker online platforms or specifying products for dynamic assemblies benefit from this board’s durable structure and consistent connectivity. For high-frequency flexing environments, this flexible circuit board retains function over an extended lifecycle and remains aligned with the precision requirements of custom pcb board design.

Design Flexibility with Manufacturing Precision

Despite the increased copper weight, the circuit still supports complex and compact pcb board design configurations. Meidear’s process allows precise trace spacing, reliable adhesion of the coverlay, and accurate registration of holes and pads. The material stack-up and finishing options support multi-interface integration, including pad plating and connector support. This flexibility in layout and finish makes it a preferred solution for engineers looking to scale projects through trusted pcb manufacturers or custom pcb maker online resources. The board’s structure can be tailored to specific routing and mechanical stress points, ensuring compatibility with detailed pcb layout services and long-term system reliability.

Use Scenarios

High‑Power Flexible Interconnects in Industrial Equipment

In industrial environments—such as motor control systems, power conversion modules, and automation hardware—high current must flow reliably through flexible channels. This 3oz heavy copper flexible circuit board provides stable performance under load and motion. During installation, the layout ensures that bends occur in designated areas while connector pads remain reinforced. The high copper content supports elevated current with minimal voltage loss or heat concentration. These properties help manufacturers reduce failure rates and optimize efficiency in industrial settings that rely on custom pcb board design and proven pcb manufacturers for power-related subsystems.

Replacement & Maintenance in Power Systems

For field-replaceable units in energy systems—such as battery management circuits or inverter control boards—this heavy copper flex pcb offers the robustness needed for safe handling and reinstallation. Its fatigue-resistant build allows for repeated flexing during maintenance without degrading signal integrity or mechanical strength. When used in modular power platforms, its enhanced copper paths prevent overheating during load spikes, while flexible layering ensures smooth installation even in tight enclosures. As a result, this product meets the expectations of engineers selecting designs via pcb maker online systems who value performance retention in replaceable modules or repairable assemblies.

Integration in Compact Devices with Heat/Current Demands

Compact systems like portable power packs, miniature drive systems, or ruggedized control units require circuits that manage both thermal and mechanical constraints. This heavy copper flex board pcb supports tight folding geometries while handling sustained current throughput. Its enhanced conductor thickness lowers electrical resistance and spreads heat evenly, preventing failure in high-density enclosures. This makes it suitable for use in advanced device platforms that need durable routing without resorting to rigid boards. For developers working with scalable pcb layout services or procurement through online pcb manufacturers, this FPC offers a reliable bridge between power handling and spatial efficiency.

About Us

Meidear specializes in the production of high-quality flexible circuit board solutions, including standard and heavy copper flex pcb products. Its in-house capabilities cover substrate processing, copper patterning, multi-layer lamination, and coverlay application, enabling the production of custom configurations for industrial and custom-defined electronic applications. Meidear supports customers across prototyping and volume production stages, aligning manufacturing precision with layout intent. Through a controlled fabrication workflow and rigorous testing protocols—including electrical performance, mechanical durability, and bend endurance—the company ensures consistent outcomes.

Clients seeking advanced pcb layout services benefit from Meidear’s expertise in trace optimization, copper balancing, and connector pad integration. Additionally, Meidear provides quoting and design support for engineers sourcing through pcb maker online platforms. By combining technical depth with scalable production, Meidear stands as a capable and dependable choice among pcb manufacturers, serving industries where flexible circuits are critical for performance, reliability, and space efficiency.

FAQ

What is the copper thickness used in this flexible circuit board?

It uses approximately 3oz of copper per square foot (~0.107 mm thickness), which is significantly thicker than standard flex PCBs, enabling better current capacity and structural resilience.

Is this heavy copper flex PCB suitable for frequent bending environments?

Yes, it is engineered with reinforced layering and optimized bend zones, making it ideal for high-cycle applications that demand both electrical continuity and mechanical durability.

How does this product compare with typical options offered by pcb manufacturers?

Compared to standard products, this heavy copper FPC is more durable under stress, offers higher current support, and reflects the advanced engineering capacity of experienced pcb manufacturers.

Can I use this design within a custom pcb layout services framework?

Absolutely. The board supports customized trace geometries, interface configurations, and connector types, making it fully compatible with advanced pcb layout services.

Is this product available through pcb maker online ordering systems?

Yes, Meidear supports online ordering workflows, allowing engineers to upload specifications and receive quotes for this 3oz heavy copper flexible circuit board.

Get your heavy copper flex PCB built to spec—submit your design for custom production today!

This heavy copper flexible circuit board is built using approximately 3oz of copper per square foot, significantly increasing its durability and current-handling capability. It uses a flexible base material capable of enduring repeated bends without delamination. The thick copper layer enhances the mechanical resilience of the flex pcb while maintaining a consistent structure through layered insulation. At each stage of production—from copper lamination to coverlay application—careful process control ensures that the resulting pcb board design meets both mechanical and electrical requirements. With optimized trace width, spacing, and soldering pads, the product provides excellent structural integrity. These features are essential for clients working with pcb layout services or sourcing reliable designs from experienced pcb manufacturers aiming for high-current applications.

Electrical Performance and Thermal Reliability

The 3oz copper layer allows this flex pcb to carry higher currents with reduced resistive loss, making it ideal for systems that require efficient power delivery over bendable substrates. The increased copper cross-section reduces heat buildup, while the flexible polyimide substrate maintains thermal stability. The layered construction ensures electrical isolation and high voltage resistance, making this a dependable choice for mission-critical applications. For engineers working on power systems or complex devices requiring thermal resilience, this product delivers the structural and electrical consistency they expect from high-end flex board pcb solutions. It also allows precise customization, making it suitable for advanced pcb layout services and tailored builds by capable pcb manufacturers.

Manufacturing Process and Quality Control

Producing a 3oz heavy copper flexible circuit board demands advanced techniques to ensure clean etching, stable layering, and optimal flexibility. Meidear uses high-quality copper foil, chemical etching, and multi-stage lamination to construct circuits that meet strict tolerance standards. Post-fabrication, each board undergoes electrical testing, visual inspection, and bend-cycle stress validation to confirm durability. The entire process aligns with the expectations of professional pcb manufacturers and clients who rely on pcb maker online systems for both prototyping and scaled production. From layout verification to final delivery, the board reflects the required performance standards of modern pcb board design workflows.

Product Advantages

High Current Transmission with Structural Stability

This heavy copper flex pcb delivers enhanced current-carrying capability due to its ~3oz copper structure. Traces are optimized to reduce resistance and voltage drop under load, making the product ideal for power-intensive systems. It withstands sustained current flow without thermal degradation, thanks to its high-conductivity copper paths and reinforced insulation layers. The high current density support, combined with mechanical flexibility, gives engineers a rare combination of strength and form factor efficiency. These benefits are directly relevant to industrial pcb layout services and OEMs seeking high-load flex board pcb options manufactured by reliable pcb manufacturers.

Fatigue Resistance in Dynamic Applications

The increased copper thickness, when paired with flexible substrates and properly engineered bend zones, reduces the risk of cracking and electrical failure during repeated flexing. Meidear reinforces connection points and soldering pads, ensuring secure mechanical stability even under vibration or stress. The mechanical fatigue resistance adds measurable longevity to the overall system. Designers sourcing through pcb maker online platforms or specifying products for dynamic assemblies benefit from this board’s durable structure and consistent connectivity. For high-frequency flexing environments, this flexible circuit board retains function over an extended lifecycle and remains aligned with the precision requirements of custom pcb board design.

Design Flexibility with Manufacturing Precision

Despite the increased copper weight, the circuit still supports complex and compact pcb board design configurations. Meidear’s process allows precise trace spacing, reliable adhesion of the coverlay, and accurate registration of holes and pads. The material stack-up and finishing options support multi-interface integration, including pad plating and connector support. This flexibility in layout and finish makes it a preferred solution for engineers looking to scale projects through trusted pcb manufacturers or custom pcb maker online resources. The board’s structure can be tailored to specific routing and mechanical stress points, ensuring compatibility with detailed pcb layout services and long-term system reliability.

Use Scenarios

High‑Power Flexible Interconnects in Industrial Equipment

In industrial environments—such as motor control systems, power conversion modules, and automation hardware—high current must flow reliably through flexible channels. This 3oz heavy copper flexible circuit board provides stable performance under load and motion. During installation, the layout ensures that bends occur in designated areas while connector pads remain reinforced. The high copper content supports elevated current with minimal voltage loss or heat concentration. These properties help manufacturers reduce failure rates and optimize efficiency in industrial settings that rely on custom pcb board design and proven pcb manufacturers for power-related subsystems.

Replacement & Maintenance in Power Systems

For field-replaceable units in energy systems—such as battery management circuits or inverter control boards—this heavy copper flex pcb offers the robustness needed for safe handling and reinstallation. Its fatigue-resistant build allows for repeated flexing during maintenance without degrading signal integrity or mechanical strength. When used in modular power platforms, its enhanced copper paths prevent overheating during load spikes, while flexible layering ensures smooth installation even in tight enclosures. As a result, this product meets the expectations of engineers selecting designs via pcb maker online systems who value performance retention in replaceable modules or repairable assemblies.

Integration in Compact Devices with Heat/Current Demands

Compact systems like portable power packs, miniature drive systems, or ruggedized control units require circuits that manage both thermal and mechanical constraints. This heavy copper flex board pcb supports tight folding geometries while handling sustained current throughput. Its enhanced conductor thickness lowers electrical resistance and spreads heat evenly, preventing failure in high-density enclosures. This makes it suitable for use in advanced device platforms that need durable routing without resorting to rigid boards. For developers working with scalable pcb layout services or procurement through online pcb manufacturers, this FPC offers a reliable bridge between power handling and spatial efficiency.

About Us

Meidear specializes in the production of high-quality flexible circuit board solutions, including standard and heavy copper flex pcb products. Its in-house capabilities cover substrate processing, copper patterning, multi-layer lamination, and coverlay application, enabling the production of custom configurations for industrial and custom-defined electronic applications. Meidear supports customers across prototyping and volume production stages, aligning manufacturing precision with layout intent. Through a controlled fabrication workflow and rigorous testing protocols—including electrical performance, mechanical durability, and bend endurance—the company ensures consistent outcomes.

Clients seeking advanced pcb layout services benefit from Meidear’s expertise in trace optimization, copper balancing, and connector pad integration. Additionally, Meidear provides quoting and design support for engineers sourcing through pcb maker online platforms. By combining technical depth with scalable production, Meidear stands as a capable and dependable choice among pcb manufacturers, serving industries where flexible circuits are critical for performance, reliability, and space efficiency.

FAQ

What is the copper thickness used in this flexible circuit board?

It uses approximately 3oz of copper per square foot (~0.107 mm thickness), which is significantly thicker than standard flex PCBs, enabling better current capacity and structural resilience.

Is this heavy copper flex PCB suitable for frequent bending environments?

Yes, it is engineered with reinforced layering and optimized bend zones, making it ideal for high-cycle applications that demand both electrical continuity and mechanical durability.

How does this product compare with typical options offered by pcb manufacturers?

Compared to standard products, this heavy copper FPC is more durable under stress, offers higher current support, and reflects the advanced engineering capacity of experienced pcb manufacturers.

Can I use this design within a custom pcb layout services framework?

Absolutely. The board supports customized trace geometries, interface configurations, and connector types, making it fully compatible with advanced pcb layout services.

Is this product available through pcb maker online ordering systems?

Yes, Meidear supports online ordering workflows, allowing engineers to upload specifications and receive quotes for this 3oz heavy copper flexible circuit board.

Get your heavy copper flex PCB built to spec—submit your design for custom production today!