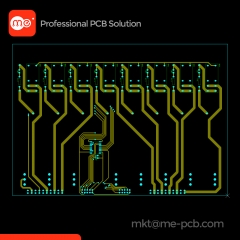

FR4 2.4mm 3/3Oz Green Soldermask for high current load Board

FR4 2.4mm 3/3Oz Green Soldermask for high current load Board-Heavy Copper PCB for High-Current Applications

In the world of electronics, power density is a constant challenge. Standard PCBs often fail under extreme thermal and electrical stress. Our Heavy Copper PCB is the engineered solution, designed specifically to manage high current load, dissipate intense heat, and provide unparalleled mechanical strength in demanding environments. Utilizing a robust FR4 KB 6160 substrate and featuring a substantial 3oz (105um) copper thickness, these boards are built for reliability and performance where it matters most.

What is a Heavy Copper PCB?

A Heavy Copper PCB is a circuit board defined by its exceptionally thick copper cladding, significantly beyond the 1oz (35um) typical of standard boards. This isn't a minor upgrade; it's a fundamental redesign for power integrity. The primary function of the heavy copper layers is to carry significantly higher currents, provide superior thermal management, and enhance the board's overall durability. When your design involves power supplies, motor controllers, or automotive systems, a standard FR4 PCB simply won't suffice. You need the robust foundation that only a dedicated heavy copper board can provide.

Engineering for Extreme Conditions: The High Current Load Board

The term "High current load Board" is more than just a description; it's a performance specification. When currents surge through a circuit, they generate heat proportional to the square of the current (I²R losses). A thin trace on a standard PCB will overheat, leading to potential failure. Our Heavy Copper PCB for High current load applications solves this by providing a much wider conductive pathway. The substantial copper thickness—3oz (105um) in this case—dramatically reduces electrical resistance, allowing for higher current carrying capacity in a more compact space and efficiently dissipating the generated heat into the board structure.

The Anatomy of Reliability: Materials and Construction

The performance of a heavy copper board hinges on its material composition and construction quality.

-

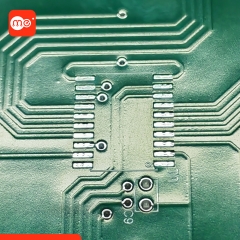

Core Substrate: We use high-grade FR4 KB 6160, a material known for its excellent thermal stability, mechanical strength, and flame-retardant properties. This ensures the board remains dimensionally stable and reliable even under thermal cycling.

-

Copper Thickness: The heart of this product is the 3oz (105um) copper thickness on both inner and outer layers. This is a key differentiator, providing the necessary cross-sectional area for high-current paths.

-

Board Thickness: To complement the heavy copper and ensure overall structural rigidity, we offer a standard finished 2.4mm board thickness. This specific dimension contributes to the board's ability to withstand mechanical stress and vibration.

-

Layer Count & Solder Mask: This particular board is a versatile 2 layers PCB design, ideal for a vast range of power applications. It is finished with a standard Soldermask color: Green, providing protection against oxidation and short circuits.

The manufacturing process for such boards requires techniques, as etching and plating thick copper foils present unique challenges. Our expertise ensures clean traces, without undercutting, and reliable plated through-holes that can handle the thermal expansion mismatch between the copper and the FR4 material.

Product Advantages

Choosing our Heavy Copper PCBs translates into direct, tangible benefits for your product's performance, reliability, and lifetime.

-

Superior Current Carrying Capacity: This is the primary advantage. The 3oz (105um) copper thickness allows our boards to carry currents that would melt or damage standard PCBs. This makes them perfect for power converters, welding equipment, and battery charging systems. You can design more powerful products without increasing the board size unnecessarily.

-

Enhanced Thermal Management: Copper is an excellent conductor of heat. The thick copper layers act as a massive heat sink, pulling heat away from critical components like power transistors, IGBTs, and connectors. This passive cooling effect lowers operating temperatures, increases component lifespan, and improves long-term reliability, reducing the need for active cooling solutions in many cases.

-

Increased Mechanical Strength: The heavy copper plating strengthens the plated through-holes (PTHs) and the overall board structure. This is crucial for connectors that are frequently plugged and unplugged, or for applications subject to high vibration or shock. The robust 2.4mm board thickness further contributes to this mechanical integrity.

-

High Density and Space Efficiency: By using a Heavy Copper PCB, you can consolidate what would normally require multiple standard boards or bulky bus bars into a single, compact 2 layers PCB. The thick copper allows for the creation of high-current paths in a smaller footprint, enabling more innovative and denser product designs.

-

Long-Term Reliability and Durability: The combination of high-quality FR4 KB 6160 substrate, robust construction, and excellent thermal performance makes these boards exceptionally reliable. They can withstand repeated thermal cycling (expansion and contraction) without failure of the copper traces or de-lamination, ensuring your product operates flawlessly for years.

-

Diverse Service Portfolio:

Meidear-PCB is not a niche player but a full-service provider. This is a significant strength when promoting a product like a Heavy Copper PCB. Potential clients often seek suppliers who can handle all their PCB needs, from standard FR4 PCB to advanced types. Highlighting heavy copper expertise alongside their other services builds confidence and positions ME-PCB as a technical leader.

-

Target Audience Alignment: The website's content suggests they serve industries such as automotive, industrial controls, power electronics, and telecommunications. These are precisely the sectors that require High current load Board solutions. The messaging for the Heavy Copper PCB should be tailored to address the specific pain points (e.g., thermal failure, power density) in these verticals.

-

Opportunity for Enhanced Technical Marketing: While the website lists heavy copper as a capability, there is a prime opportunity to dive deeper into the "why" and "how," exactly as this product page aims to do. Creating dedicated, SEO-rich content for this specific product line will attract highly qualified traffic from engineers and procurement specialists searching for these technical solutions by name.

-

Leveraging the "One-Stop Solution" Message: The website's promise of a complete solution is a powerful selling point. The call-to-action for the Heavy Copper PCB should seamlessly integrate this, encouraging visitors to leverage ME-PCB's end-to-end expertise—from design consultation and manufacturing to final assembly—for their most demanding power projects.

Call to Action

Ready to power your next innovation with unwavering reliability? Our expert team is here to provide you with a professional one-stop Heavy Copper PCB solution, from design review to final delivery.

Get professional one stop PCB solution from us! Request your free quote today!

www.me-pcb.com

www.linkedin.com/in/mepcb