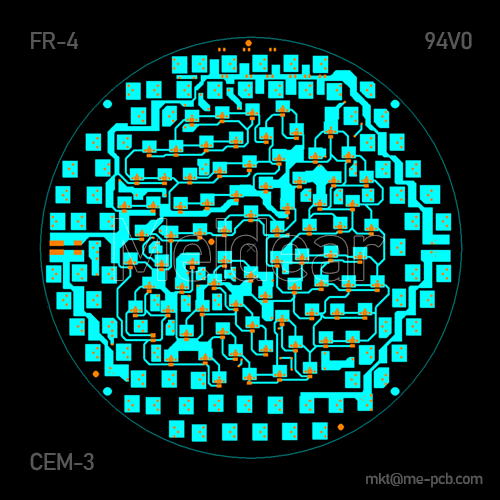

Single-double Sided PCB

OEM Fr4 94V0 Pcb Printed Circuit Board Pcb Manufacturer shenzhen Supplier

OEM Fr4 94V0 Pcb Printed Circuit Board Pcb Manufacturer

shenzhen Supplier

shenzhen Supplier

Description

| Material: | FR-4 / CEM-1 / CEM-3 (KB, Shengyi or Nanya), TG>=130, 150, 170℃; CTI>=175, 600V; |

| Finished board thickness: | 0.4-3.2mm, as your requirement; |

| Finished copper thickness: | 35, 70, 105, 140um, as your requirement; |

| Solder mask: | Green, White, Black, Yellow, Blue, Red, as your requirement; |

| Silkscreen: | Black, White, Yellow, Gray, as your requirement; |

| Surface treatment: | OSP, HASL Lead-free, Immersion Gold, Immersion Tin, Immersion Silver; |

| Tolerance of hole: | size, +/-0.05mm; position, +/-0.075mm; |

| Tolerance of outline: | milling, +/-0.1mm; V-groove, +/-0.2mm. |

Why Do We Use Copper to Make PCB Traces?

A printed circuit board (PCB) is made up of several layers, including the substrate, traces, soldermask, and silkscreen. The traces are a crucial element, because they carry the electrical signals to different components across the board. Without the traces, the PCB wouldn’t function.

If you have some pcb project,

pls send your gerber files to mkt@me-pcb.com with email.

Material Composition and Specification

This PCB is built with FR‑4 / CEM‑1 / CEM‑3 materials (brands like KB, Shengyi or Nanya possible) offering TG ratings ≥130°C, 150°C, or 170°C depending on requirement, and CTI ≥175 at 600V, ensuring flame retardancy at the UL94V‑0 level. Finished board thickness can range from 0.4mm to 3.2mm, copper thickness options include 35, 70, 105, 140 µm per your design demands. Solder mask colors (green, white, black, yellow, blue, red) and silkscreen colors (black, white, yellow, gray) are customizable. Surface treatment options cover OSP, lead‑free HASL, immersion gold, immersion tin, immersion silver. Hole tolerances: size ±0.05mm, position ±0.075mm; outline milling tolerance ±0.1mm; V‑groove tolerance ±0.2mm. These specifications support high precision performance needed in pcb board design and when ordering from pcb maker online platforms.

Manufacturing Accuracy and Design Flexibility

The board processing includes accurate hole tolerances, outline control, and flexible finish choices to meet diverse design constraints. With copper and board thickness choices, and a wide palette of solder mask & silkscreen colors, designers can tailor boards for different visibility, mechanical, or environmental needs. The tight tolerances in hole size and position ensure that components fit reliably, maintaining consistency across production‑scale runs. Custom choices in surface finish (such as immersion gold) aid in solder joint quality, while the flexible options in mask and color allow for functional labeling or aesthetics. This attention to precision enables strong outcomes in pcb layout services, especially for designs where line‑to‑hole alignment or component footprint matching is critical.

Target Users and Application Context

This PCB is intended for electronics engineers, OEMs, and system designers who require flame-retardant FR4‑94V0 material for safety compliance, mid-volume board runs, and custom finish options. Use cases include industrial control panels, LED lighting modules, power conversion modules, or devices requiring custom color and finish for branding or environmental marking. Users placing orders via pcb manufacturers or through pcb maker online catalogs will find these configurable options (thickness, copper weight, surface finish, mask color) especially valuable. Designs that also incorporate partial flex (though this board is rigid FR4/CEM) may benefit when paired with flex sections or rigid-to-flex transition boards, where matching interface thickness or finish reduces assembly mismatch.

Product Advantages

1. Versatile Thickness & Copper Weight Options

Having a wide span of board thickness from 0.4mm to 3.2mm alongside copper weights of 35, 70, 105, 140 µm allows striking balance between mechanical strength, thermal behavior, and weight. For designs that require lightweight boards or tight space envelopes, thinner boards reduce material bulk; for power or thermal load, thicker copper weights improve current carrying and reduce heating. This variety supports demanding pcb layout services where the physical constraints (height, weight, thermal dissipation) matter, and is helpful for customers sourcing from pcb manufacturers or pcb maker online platforms who need to optimize both performance and manufacturing cost.

2. Custom Surface Finish & Color Flexibility

Multiple surface finish types (OSP, lead‑free HASL, immersion gold, etc.) along with a broad range of solder mask and silkscreen color choices enable adaptation to different requirements: soldering reliability, environmental resistance, visual inspection, product aesthetics. For example, immersion gold enhances solder joint quality and contact pad durability; mask and silkscreen color selection helps with readability of labels or integration into product color schemes. In applications like LED lighting or control panels, color contrast and finish quality can affect safety, durability, and maintenance. This flexibility is particularly useful when working with flexible circuit board sections or when rigid boards need matching surface consistency.

3. Flame Retardancy and Compliance Assurance

The FR‑4 / CEM materials meet 94V‑0 standard flammability classification, with TG rating options ≥130‑170°C, and CTI ≥175 at 600V. That ensures the board resists ignition, limits spread of flame, and maintains insulation properties under higher voltage, which is critical for safety‑sensitive electronics. Compliance with these parameters gives confidence in industrial, lighting, and safety equipment applications. For engineers needing pcb board design solutions that comply with flame safety, or manufacturers offering boards via pcb manufacturers supply chains, this compliance reduces risk and helps in regulatory or certification submissions.

Use Scenarios

Factory & Industrial Assembly Environments

In electronics manufacturing plants, power supply production, LED module assembly, or control box fabrication, ambient temperature, handling, and solder reflow cycles impose mechanical and thermal stress. Using FR4‑94V0 material with controlled thickness and copper weight ensures boards do not warp or degrade during soldering. Surface finishes like immersion gold or HASL resist oxidation in humid or chemically aggressive environments. Designers using pcb layout services will appreciate consistent registration of holes and outlines, as misalignment at industrial scale causes assembly defects. Ordering through pcb maker online channels for mid‑volume helps ensure that what is specified (thickness, finish, mask color) is accurately reproduced.

Design & Prototyping Workflow

When a designer submits Gerber or CAM files to request custom prototype boards, these specifications allow freedom to test variants: different copper thickness for heat load, mask color for readability, finish for solderability. The tolerances in hole and outline dimension help ensure that prototypes match production boards. Users can trial multiple surface treatments (e.g. compare IMMERSION GOLD versus HASL), adjust board thickness for mechanical fit. This is especially relevant for customers leveraging pcb makers online or pcb manufacturers who provide rapid prototype turnaround before full production.

Safety‑Critical or Aesthetic Product Integration

Products intended for consumer safety, such as control panels, appliances, or lighting fixtures often need adherence to flammability standards; FR4‑94V0 material ensures flame retardancy. At the same time, color of solder mask or silkscreen and finish type (gold, silver, etc.) contribute to aesthetic and branding value. For installations exposed to public view, a clean appearance, legible silkscreen, smooth finish are important. Also, in electronic products with moderate vibration or thermal cycles (e.g. lighting fixtures, industrial monitors), robust material and finish choices ensure long life. Such scenarios benefit from combining flex board PCB where needed or matching rigid sections with those boards for interface sections.

About Us

Meidear is a professional pcb board design and fabrication company offering rigid, flex, and multilayer PCB types. The company supports materials including FR4, CEM‑1, CEM‑3, with flame‑retardant rating 94V‑0, TG values of 130‑170°C, and copper thickness options from 35µm up to 140µm. Surface finishes include OSP, lead‑free HASL, immersion gold, immersion tin, and immersion silver. Manufacturing tolerances include hole size ±0.05mm, position ±0.075mm; outline milling ±0.1mm; V‑groove ±0.2mm. Mask colors cover multiple hues; silkscreen choices also available. Meidear accepts customized designs, prototype runs, and small‑to‑medium volume orders, serving clients relying on online quoting, Gerber file submission, and precision pcb layout services.

FAQ

What finishes are available and why does finish type matter for pcb layout services?

Meidear offers OSP, lead‑free HASL, immersion gold, immersion tin, immersion silver finishes; finish impacts solderability, oxidation resistance, pad durability which are critical during soldering and long‑term use.

What board thicknesses and copper weights can be ordered via pcb maker online?

Boards with thickness from 0.4mm to 3.2mm and copper weights of 35, 70, 105, or 140 µm are accepted; customers can select these when submitting design files online.

What tolerance levels apply to holes and board outline?

Hole size tolerance ±0.05mm, position tolerance ±0.075mm; board outline milling tolerance ±0.1mm, V‑groove outline ±0.2mm. These tolerances support accurate component placement and assembly.

Is the material FR4‑94V0 flame retardant?

Yes, the base materials (FR4, CEM‑1, CEM‑3) are rated UL94V‑0; they meet TG ratings ≥130‑170°C and CTI ≥175, ensuring flame retardancy and electrical insulation for safety‑sensitive applications.

Can this PCB type accommodate flex pcb or rigid‑flex configurations?

This product is a rigid material (FR4 or CEM); while not a true flex PCB, it can interface with flex sections or be part of rigid‑flex designs if specified. For frequent bending or dynamic flexing, dedicated flexible circuit board material is more suitable.