Industrial Control PCBA & PCB Assembly Services | Reliable Solutions for Automation and Robotics

In the rapidly evolving world of electronics, the heart of every device is its printed circuit board assembly (PCBA). ME-PCB stands at the forefront of this industry, offering end-to-end PCB assembly services that transform your designs into fully functional, high-performance electronic products. We are your trusted partner, providing seamless integration from raw PCB manufacturing to final assembly and testing.

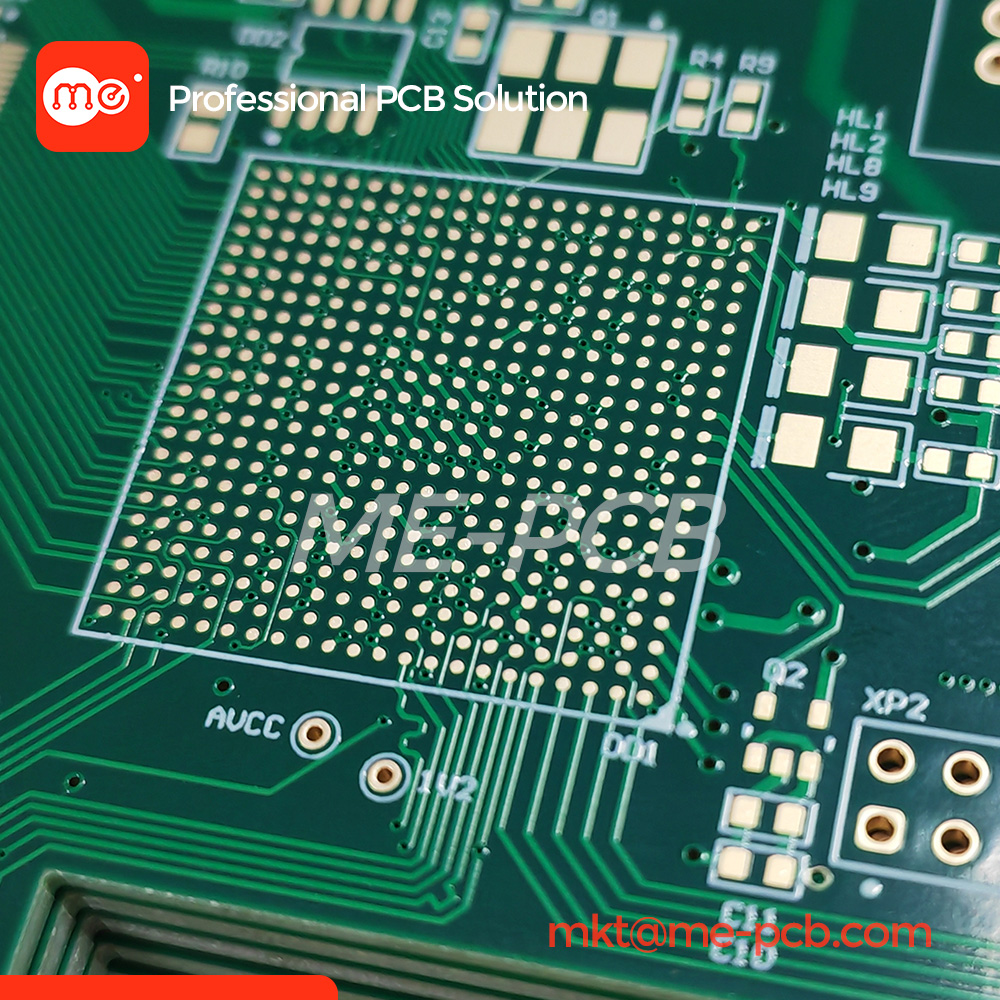

Our core strength lies in our advanced manufacturing capabilities. We utilize state-of-the-art SMT (Surface Mount Technology) lines equipped with high-speed placement machines and precision stencil printers. This allows us to accurately place thousands of microscopic components onto boards with incredible speed and consistency, which is essential for complex and dense designs. Furthermore, our technicians are highly skilled in handling complex BGA (Ball Grid Array) components. Using X-ray inspection systems, we ensure perfect soldering and alignment underneath these chips, guaranteeing integrity and preventing future field failures.

We understand the critical need for reliability in specific sectors. This is why our processes are meticulously calibrated for producing industrial control PCBA. These boards power machinery, automation systems, and control units that operate in harsh environments with extreme temperatures, vibrations, and continuous runtime. We use select materials and stringent quality control protocols to ensure these assemblies meet the highest standards of durability and long-term performance.

Our service offering is a comprehensive journey. It begins with our expert DFM (Design for Manufacturability) analysis, where we review your design files to identify and rectify potential production issues early, saving you time and cost. This is followed by our precise PCB manufacturing process, where we produce high-quality bare boards. The baton is then passed to our assembly floor, where components are sourced, placed, soldered, and meticulously inspected. Finally, every assembly undergoes rigorous testing, including In-Circuit Testing (ICT) and Functional Circuit Testing (FCT), to verify that it performs exactly as intended. By managing this entire process under one roof, ME-PCB ensures superior quality control, faster turnaround times, and a streamlined communication channel for our customers.

Choosing ME-PCB as your PCB assembly services partner unlocks a multitude of advantages that streamline your production and enhance product quality.

-

Uncompromising Quality and Reliability: Our commitment to quality is embedded in every step. From using premium substrates in PCB manufacturing to employing AOI (Automated Optical Inspection) and X-ray for BGA and SMT components, we leave nothing to chance. This results in lower defect rates and higher field reliability, which is paramount for industrial control PCBA and other critical applications.

-

Advanced Technological Expertise: Our investment in modern equipment and continuous training of our staff ensures we can handle the most complex assemblies. Our proficiency with fine-pitch components, micro-BGAs, and mixed-technology boards (SMT & thru-hole) sets us apart from competitors.

-

One-Stop Shop Convenience: We eliminate the hassle of dealing with multiple vendors. ME-PCB provides a full spectrum of services, including PCB fabrication, component sourcing and procurement, assembly, testing, and packaging. This integrated approach reduces logistical complexities, minimizes lead times, and provides you with a single point of accountability.

-

Cost-Effectiveness and Value Engineering: Our efficient processes and economies of scale allow us to offer highly competitive pricing without sacrificing quality. Our DFM analysis service actively helps you optimize your design for manufacturability, often suggesting changes that reduce layer counts or simplify assembly, leading to significant cost savings.

-

Responsive Customer Support and Transparency: We pride ourselves on clear and proactive communication. You get a dedicated project manager, real-time order tracking, and responsive support to address any queries. We believe in building long-term partnerships based on trust and mutual success.

The robust and precise PCB assembly services provided by ME-PCB are critical to the functionality and innovation of countless industries and applications.

-

Industrial Automation and Control Systems: This is a primary application for our industrial control PCBA. Our boards are integral to PLCs (Programmable Logic Controllers), motor drives, sensors, and human-machine interfaces (HMIs) that operate manufacturing plants and automated machinery. The reliability ensured by our SMT and BGA processes is non-negotiable here, as downtime can be extremely costly.

-

Telecommunications and Networking: Routers, switches, base stations, and signal transceivers rely on high-speed, multi-layer PCBs with dense component placement. Our advanced PCB manufacturing and assembly capabilities ensure signal integrity and thermal management necessary for handling high-frequency data transmission.

-

Medical Electronics: Medical devices, from patient monitors and diagnostic equipment (like ECG and ultrasound machines) to portable wearable health tech, require the utmost reliability and precision. Our controlled assembly environment and strict adherence to quality standards produce PCBA that meets the critical safety and performance demands of the medical field.

-

Consumer Electronics and IoT: The Internet of Things (IoT) revolution is powered by sophisticated yet cost-effective PCBAs. We assemble boards for smart home devices, wearables, entertainment systems, and personal gadgets. Our ability to scale from prototype to mass production helps innovators bring their products to market quickly.

-

Automotive Electronics: Modern vehicles are equipped with dozens of electronic control units (ECUs) for engine management, infotainment, ADAS (Advanced Driver-Assistance Systems), and more. We produce robust PCBA that can withstand the temperature extremes, vibrations, and longevity requirements of the automotive industry.

-

Power Supply and Energy Management: Inverters, battery management systems (BMS), and smart grid technology all depend on durable and efficient circuit boards. Our expertise ensures these power-dense applications are built with proper materials and layout to handle high currents and remain stable over time.