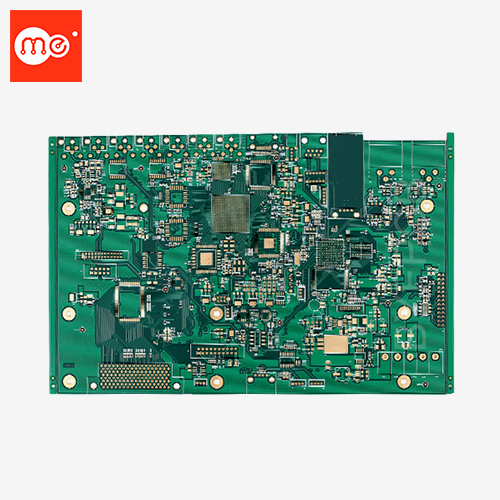

Multilayer PCB

Security & Protection Product Motherboard Custom PCB

Item No.: MPCB00162

Meidear provides PCB for Security & Protection production, which includes Alarm, Security Systems, Car Safety, Lock, Fire Control, Safety Glasses, Smart Card, Lifesaving, Surveillance Control,Safety Products and more

Description

Security & Protection Product Usually need to use the motherboard.

Shenzhen Meidear Co., Ltd. is a professional manufacturer who dedicated to high-precision multilayer PCB plate making, SMT, soldering, and one-stop service! High Precision! High difficulty! high standard! It has always been our constant pursuit and positioning!

Material & Construction Details

The motherboard PCB is fabricated using rigid FR‑4 laminate material, with standard thickness around 1.6mm, copper weight suitable for signal and power traces. The board includes solder mask and silkscreen layers for component identification and protection. Edge plating, through‑holes, and mounting holes are fabricated per design files. The laminate meets insulation and dielectric strength required for security protection equipment. The board supports design files submitted online, enabling engineers to leverage pcb board design specifications with controlled copper trace widths and clear component markings. Surface finish types are available to protect copper pads against corrosion and ensure reliable electrical connections.

Manufacturing Process & Design Compatibility

Order process begins with Gerber or CAD files, which are reviewed for manufacturability, hole placement, component footprint accuracy, and outline definition. After drilling and copper plating of through‑holes, the board proceeds through solder mask application and silkscreen printing. The controlled process ensures alignment of layers and clearances that align with pcb layout services standards. Protective finishes and mask application ensure that the board meets functional requirements in security electronics, such as grounding, signal integrity, and isolation. Customization in finish, mask color, and silkscreen color supports customer aesthetic or compliance needs, especially when ordering from pcb maker online platforms.

Application & User Profile

This motherboard PCB is intended for security protection equipment makers, OEMs of access control, surveillance systems, and similar electronics requiring robust protection and reliable performance. Users designing security motherboards who need consistent specification fulfillment for signal integrity, component layout, and mechanical stability will benefit. The board is suited for deployment in indoor environments for devices like control panels, alarms, and sensor modules. Customers purchasing via pcb manufacturers or online quoting services will find the configuration flexibility useful, especially where variants in copper thickness, finish, mask or silkscreen are required for differing protection standards or operational conditions.

Product Advantages

1. Robust Construction for Signal & Power Stability

A rigid FR‑4 base with standard thickness delivers mechanical stability and maintains trace integrity under thermal cycling. Copper weights adequate for carrying required currents enable stable power distribution across motherboard plane areas. The inclusion of solder mask protects exposed copper from oxidation and environmental damage, while silkscreen ensures accurate component identification. These properties support pcb layout services that demand reliable trace widths, spacing, and pad sizes, minimizing signal loss or electrical failures in security applications.

2. Custom Finishes and Protective Layers

Protective finishes on copper pads improve lifespan in environments with moisture or pollution. Surface treatments prevent corrosion and enhance solder joint reliability. Solder mask layer adds insulation and prevents unintended short circuits. Silkscreen marking aids assembly and maintenance. Custom choices in mask/silkscreen color and finish type allow adaptation to branding, compliance, or visibility needs. For OEMs procuring through pcb maker online or via direct quotations, these options increase value without significantly increasing cost.

3. Precision Compatibility and Design Flexibility

Controlled hole placements, component layout alignment, and board outline milling ensure that design files translate accurately into manufactured boards. The process supports various mounting and connector types typical in security devices. Alignment of pads, vias, and edge connectors ensures reliable interconnects. Flexibility in design, including support for varying copper weights and finish types, enables adaptation to different load, signal, and environmental requirements. This aligns with expectations of customers seeking flex board pcb integration or reference to flexible circuit board interfaces, though this motherboard is rigid.

Use Scenarios

Security Equipment Production Environment

In factory or small‑volume production of security panels, access control units, or surveillance motherboards, operating conditions include clean assembly, solder reflow, cleaning, and quality inspection. The rigid FR‑4 motherboard PCB resists warpage during thermal processes. Protective solder mask and finish guard copper from oxidation. These stability and protective features align with pcb manufacturers standards for repeatable production runs.

Design & Prototyping with Online Platforms

Engineers submit Gerber or CAD files through pcb maker online portals or direct quotation workflows. They specify copper thickness, board finish, solder mask color, and silkscreen. Prototype boards allow verification of layout, alignment, and connector placement. Adjustments can be made before scaling to full production. This workflow is typical when using pcb layout services, enabling iteration with minimized risk.

Deployment in Security Systems

When installed in surveillance, control, alarm or sensor modules, motherboards must deliver reliable electrical connectivity, maintain insulation, and support necessary interfaces. The rigid design ensures mechanical stability when mounted in enclosures. Clear silkscreen aids maintenance, while protective finishes preserve pad integrity. Such boards often serve as the core for devices deployed indoors or in protected outdoor housings, working under moderate humidity and temperature variation. Reliability in these settings is essential; rigid boards outperform flimsy or flexible alternatives where mechanical rigidity and consistent specification are required.

About Us

Meidear is a professional pcb board design and fabrication company with capabilities in rigid PCB, flexible circuit board, and custom motherboard production. The company accepts customer‑supplied design files to deliver PCBs with specified copper thickness, solder mask and silkscreen choices, and protective finishes. Quality control includes inspection of drilling, plating, masking, and marking, ensuring electrical, mechanical alignment, and surface integrity. Meidear supports both prototype runs and medium volumes, servicing clients through pcb manufacturers supply chains and pcb maker online quoting platforms with transparency and specification consistency.

FAQ

What materials are used for the motherboard PCB, and is flame retardancy included?

The board uses rigid FR‑4 laminate material; flame retardancy depends on FR‑4 grade—standard FR‑4 provides basic flame resistance; customers may request grades meeting specific safety standards when ordering via pcb manufacturers or through pcb maker online.

Can I choose different copper thickness or finish for this security motherboard PCB?

Yes, copper thickness and surface finishes are customizable; together with solder mask and silkscreen options, these choices are supported through pcb layout services and online quoting systems.

Is this board suitable to interface with flexible circuit board or flex PCB sections?

The PCB is rigid; it does not flex. For designs needing flexible interconnects, flex PCB sections or rigid-to-flex interface configurations may be used, but those are outside the inherent rigid motherboard specifications.

How precise are the hole placements and component layout relative to design data?

Manufacturing follows submitted Gerber or CAD files, with alignment to component footprints, hole positions, board outlines, and mask/silkscreen layouts to ensure that what is designed is faithfully produced.

What kinds of security products is this motherboard PCB used in?

Typical uses include motherboards in access control panels, surveillance systems, alarm control units, sensor hubs and other security electronical devices needing stable electrical performance, accurate labeling, and consistent protective finishes.

Submit your design file now to secure a custom motherboard PCB quote!

Shenzhen Meidear Co., Ltd. is a professional manufacturer who dedicated to high-precision multilayer PCB plate making, SMT, soldering, and one-stop service! High Precision! High difficulty! high standard! It has always been our constant pursuit and positioning!

Material & Construction Details

The motherboard PCB is fabricated using rigid FR‑4 laminate material, with standard thickness around 1.6mm, copper weight suitable for signal and power traces. The board includes solder mask and silkscreen layers for component identification and protection. Edge plating, through‑holes, and mounting holes are fabricated per design files. The laminate meets insulation and dielectric strength required for security protection equipment. The board supports design files submitted online, enabling engineers to leverage pcb board design specifications with controlled copper trace widths and clear component markings. Surface finish types are available to protect copper pads against corrosion and ensure reliable electrical connections.

Manufacturing Process & Design Compatibility

Order process begins with Gerber or CAD files, which are reviewed for manufacturability, hole placement, component footprint accuracy, and outline definition. After drilling and copper plating of through‑holes, the board proceeds through solder mask application and silkscreen printing. The controlled process ensures alignment of layers and clearances that align with pcb layout services standards. Protective finishes and mask application ensure that the board meets functional requirements in security electronics, such as grounding, signal integrity, and isolation. Customization in finish, mask color, and silkscreen color supports customer aesthetic or compliance needs, especially when ordering from pcb maker online platforms.

Application & User Profile

This motherboard PCB is intended for security protection equipment makers, OEMs of access control, surveillance systems, and similar electronics requiring robust protection and reliable performance. Users designing security motherboards who need consistent specification fulfillment for signal integrity, component layout, and mechanical stability will benefit. The board is suited for deployment in indoor environments for devices like control panels, alarms, and sensor modules. Customers purchasing via pcb manufacturers or online quoting services will find the configuration flexibility useful, especially where variants in copper thickness, finish, mask or silkscreen are required for differing protection standards or operational conditions.

Product Advantages

1. Robust Construction for Signal & Power Stability

A rigid FR‑4 base with standard thickness delivers mechanical stability and maintains trace integrity under thermal cycling. Copper weights adequate for carrying required currents enable stable power distribution across motherboard plane areas. The inclusion of solder mask protects exposed copper from oxidation and environmental damage, while silkscreen ensures accurate component identification. These properties support pcb layout services that demand reliable trace widths, spacing, and pad sizes, minimizing signal loss or electrical failures in security applications.

2. Custom Finishes and Protective Layers

Protective finishes on copper pads improve lifespan in environments with moisture or pollution. Surface treatments prevent corrosion and enhance solder joint reliability. Solder mask layer adds insulation and prevents unintended short circuits. Silkscreen marking aids assembly and maintenance. Custom choices in mask/silkscreen color and finish type allow adaptation to branding, compliance, or visibility needs. For OEMs procuring through pcb maker online or via direct quotations, these options increase value without significantly increasing cost.

3. Precision Compatibility and Design Flexibility

Controlled hole placements, component layout alignment, and board outline milling ensure that design files translate accurately into manufactured boards. The process supports various mounting and connector types typical in security devices. Alignment of pads, vias, and edge connectors ensures reliable interconnects. Flexibility in design, including support for varying copper weights and finish types, enables adaptation to different load, signal, and environmental requirements. This aligns with expectations of customers seeking flex board pcb integration or reference to flexible circuit board interfaces, though this motherboard is rigid.

Use Scenarios

Security Equipment Production Environment

In factory or small‑volume production of security panels, access control units, or surveillance motherboards, operating conditions include clean assembly, solder reflow, cleaning, and quality inspection. The rigid FR‑4 motherboard PCB resists warpage during thermal processes. Protective solder mask and finish guard copper from oxidation. These stability and protective features align with pcb manufacturers standards for repeatable production runs.

Design & Prototyping with Online Platforms

Engineers submit Gerber or CAD files through pcb maker online portals or direct quotation workflows. They specify copper thickness, board finish, solder mask color, and silkscreen. Prototype boards allow verification of layout, alignment, and connector placement. Adjustments can be made before scaling to full production. This workflow is typical when using pcb layout services, enabling iteration with minimized risk.

Deployment in Security Systems

When installed in surveillance, control, alarm or sensor modules, motherboards must deliver reliable electrical connectivity, maintain insulation, and support necessary interfaces. The rigid design ensures mechanical stability when mounted in enclosures. Clear silkscreen aids maintenance, while protective finishes preserve pad integrity. Such boards often serve as the core for devices deployed indoors or in protected outdoor housings, working under moderate humidity and temperature variation. Reliability in these settings is essential; rigid boards outperform flimsy or flexible alternatives where mechanical rigidity and consistent specification are required.

About Us

Meidear is a professional pcb board design and fabrication company with capabilities in rigid PCB, flexible circuit board, and custom motherboard production. The company accepts customer‑supplied design files to deliver PCBs with specified copper thickness, solder mask and silkscreen choices, and protective finishes. Quality control includes inspection of drilling, plating, masking, and marking, ensuring electrical, mechanical alignment, and surface integrity. Meidear supports both prototype runs and medium volumes, servicing clients through pcb manufacturers supply chains and pcb maker online quoting platforms with transparency and specification consistency.

FAQ

What materials are used for the motherboard PCB, and is flame retardancy included?

The board uses rigid FR‑4 laminate material; flame retardancy depends on FR‑4 grade—standard FR‑4 provides basic flame resistance; customers may request grades meeting specific safety standards when ordering via pcb manufacturers or through pcb maker online.

Can I choose different copper thickness or finish for this security motherboard PCB?

Yes, copper thickness and surface finishes are customizable; together with solder mask and silkscreen options, these choices are supported through pcb layout services and online quoting systems.

Is this board suitable to interface with flexible circuit board or flex PCB sections?

The PCB is rigid; it does not flex. For designs needing flexible interconnects, flex PCB sections or rigid-to-flex interface configurations may be used, but those are outside the inherent rigid motherboard specifications.

How precise are the hole placements and component layout relative to design data?

Manufacturing follows submitted Gerber or CAD files, with alignment to component footprints, hole positions, board outlines, and mask/silkscreen layouts to ensure that what is designed is faithfully produced.

What kinds of security products is this motherboard PCB used in?

Typical uses include motherboards in access control panels, surveillance systems, alarm control units, sensor hubs and other security electronical devices needing stable electrical performance, accurate labeling, and consistent protective finishes.

Submit your design file now to secure a custom motherboard PCB quote!