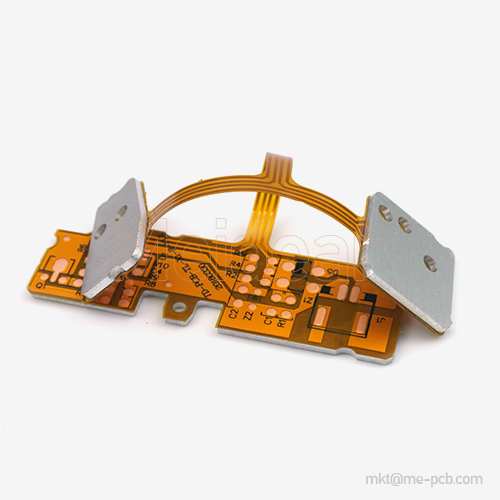

Stiffener AL Aluminum FPC backing

Item No.: F000137

Stiffener material :

AL Aluminum

SS:Stainless Steel

PI

FR4

PET

AL Aluminum

SS:Stainless Steel

PI

FR4

PET

Description

Applied In FPC Reinforcement And Component Support Zones

This aluminum stiffener is designed for use with flexible printed circuits that require localized rigidity during assembly or product integration. It targets engineers and product designers working on flexible circuits where certain areas need mechanical strength—such as connector zones, IC mounting regions, or screw holes. By bonding to specific regions of the flexible pcb, the stiffener ensures flatness, enhances solderability, and prevents deformation under pressure. It has become a staple in the toolkit of precision-focused pcb suppliers and is integrated into solutions provided by experienced pcb manufacturer teams.

High-Strength Aluminum Base With Customizable Profile

Made from precision-processed aluminum sheets, the stiffener is available in a variety of thicknesses (commonly 0.3mm–1.5mm) to accommodate structural needs without increasing total board weight. It bonds to polyimide-based flexible circuit board layers using pressure-sensitive adhesives or thermal curing films, offering high peel strength and dimensional integrity. This solution is fully compatible with SMT reflow processes, and the aluminum surface can be treated for insulation if required. Custom shaping, drilling, and edge treatment are available under the scope of professional pcb services, ensuring proper fit for both standard and custom flex pcb applications.

Widely Used In Compact, Multi-Function Electronic Assemblies

The aluminum stiffener is often employed in portable electronics, automotive modules, camera boards, and LED lighting applications. It enables mechanical protection in regions where connectors are repeatedly inserted or where components generate localized heat. OEMs and contract manufacturers rely on this solution when sourcing pcb services that involve flexible pcb assembly combining flexible pcb with rigid mechanical requirements. Its use improves reliability, reduces assembly errors, and supports mass production alignment standards recognized by top-tier pcb suppliers.

Product Advantages

Localized Rigidity Without Full Board Reinforcement

Instead of converting the entire flexible circuit into a semi-rigid structure, this aluminum stiffener provides localized support where needed. This allows for selective mechanical protection while preserving the dynamic flexibility of the rest of the flexible pcb. Applications include connector edges, BGA pads, and switch interfaces. This structure-level precision benefits designers working with advanced circut board layouts and allows pcb manufacturer teams to optimize weight, thickness, and thermal performance per region.

Enhanced Dimensional Stability Under Thermal Stress

The aluminum stiffener contributes to overall system stability by minimizing thermal warpage during high-temperature processes such as soldering or environmental exposure. Its low CTE (coefficient of thermal expansion) aligns well with polyimide and copper, reducing delamination risks during thermal cycling. For high-performance led pcb assemblies and compact power modules, this reinforcement layer maintains structural accuracy and prevents shifting of mounted components—a critical demand in advanced pcb services.

Seamless Integration Into Standard Assembly Processes

The stiffener is compatible with pick-and-place equipment, reflow soldering, and punching operations. Its shape and bonding method can be tailored for integration at specific stages of the production line without disrupting cycle times. Adhesive-backed or pre-punched aluminum formats are available for streamlined use. These features are particularly advantageous for flex pcb configurations requiring high-volume production where mechanical alignment must be preserved. Pcb suppliers offering custom lamination and cutting further enhance deployment flexibility.

Use Scenarios

Consumer Electronics Designers Reinforcing Connector Interfaces

Product engineers designing compact devices such as smartphones, tablets, or handheld sensors often face challenges related to connector reliability. Repeated mating cycles and user interaction cause stress on the FPC substrate. By integrating this aluminum stiffener, they ensure secure flatness and prevent peeling or cracking. As part of end-to-end pcb services, it adds no active function but improves the mechanical quality of flexible pcb assemblies sourced from reliable pcb suppliers.

Automotive Engineers Building Dashboard Flex Modules

FPCs used in automotive dashboards or control units must endure significant vibration and temperature fluctuation. Engineers adopt aluminum stiffeners in zones with press-fit connectors or microcontrollers to ensure board flatness and thermal consistency. In conjunction with ruggedized flexible circuit board designs, this mechanical reinforcement offers long-term durability and ease of final assembly—especially when coordinated with a trusted pcb manufacturer capable of precision pre-bonding and shape optimization.

Lighting Module Integrators Adding Thermal Protection Layers

In LED strips and lighting control units, certain components generate hotspots or require stable mounting positions. Integrators use this aluminum stiffener to support those regions while dissipating heat through conduction. It is often used under driver ICs or as a backplate in led pcb assemblies where both heat and structure need to be managed without adding excessive thickness. Its integration into flex pcb systems ensures consistent light output and reduces thermal damage during extended operation.

About Us

This circuit board provider specializes in comprehensive fabrication and value-added services, including rigid, flexible, and mixed-structure PCB configurations. With capabilities spanning aluminum, FR4, polyimide, and composite materials, the team supports industries from automotive electronics to lighting systems and consumer devices. Recognized among dependable pcb suppliers, the manufacturer offers tailored pcb services such as stiffener integration, selective lamination, and high-precision routing. By combining material engineering with production agility, the company helps clients bring complex flexible pcb and rigid-flex products to market quickly while maintaining consistency, accuracy, and long-term performance standards.

Send your aluminum stiffener flexible pcb request and receive custom specifications today!

FAQ

Can this aluminum stiffener be pre-bonded before shipping?

Yes, pre-bonding is available using thermal or pressure-sensitive adhesives based on design specs.

Is it compatible with automated assembly processes?

The stiffener is designed to work with SMT lines, punching equipment, and reflow soldering workflows.

Can insulation be applied to the aluminum surface?

Yes, an insulating film or anodizing treatment can be added if electrical isolation is required.

What thicknesses are available for the aluminum backing?

Standard options range from 0.3mm to 1.5mm; custom dimensions can be manufactured.

Are there size limitations for stiffener bonding areas?

Bonding zones can be fully customized; only the FPC layout and component clearances need to be considered.

This aluminum stiffener is designed for use with flexible printed circuits that require localized rigidity during assembly or product integration. It targets engineers and product designers working on flexible circuits where certain areas need mechanical strength—such as connector zones, IC mounting regions, or screw holes. By bonding to specific regions of the flexible pcb, the stiffener ensures flatness, enhances solderability, and prevents deformation under pressure. It has become a staple in the toolkit of precision-focused pcb suppliers and is integrated into solutions provided by experienced pcb manufacturer teams.

High-Strength Aluminum Base With Customizable Profile

Made from precision-processed aluminum sheets, the stiffener is available in a variety of thicknesses (commonly 0.3mm–1.5mm) to accommodate structural needs without increasing total board weight. It bonds to polyimide-based flexible circuit board layers using pressure-sensitive adhesives or thermal curing films, offering high peel strength and dimensional integrity. This solution is fully compatible with SMT reflow processes, and the aluminum surface can be treated for insulation if required. Custom shaping, drilling, and edge treatment are available under the scope of professional pcb services, ensuring proper fit for both standard and custom flex pcb applications.

Widely Used In Compact, Multi-Function Electronic Assemblies

The aluminum stiffener is often employed in portable electronics, automotive modules, camera boards, and LED lighting applications. It enables mechanical protection in regions where connectors are repeatedly inserted or where components generate localized heat. OEMs and contract manufacturers rely on this solution when sourcing pcb services that involve flexible pcb assembly combining flexible pcb with rigid mechanical requirements. Its use improves reliability, reduces assembly errors, and supports mass production alignment standards recognized by top-tier pcb suppliers.

Product Advantages

Localized Rigidity Without Full Board Reinforcement

Instead of converting the entire flexible circuit into a semi-rigid structure, this aluminum stiffener provides localized support where needed. This allows for selective mechanical protection while preserving the dynamic flexibility of the rest of the flexible pcb. Applications include connector edges, BGA pads, and switch interfaces. This structure-level precision benefits designers working with advanced circut board layouts and allows pcb manufacturer teams to optimize weight, thickness, and thermal performance per region.

Enhanced Dimensional Stability Under Thermal Stress

The aluminum stiffener contributes to overall system stability by minimizing thermal warpage during high-temperature processes such as soldering or environmental exposure. Its low CTE (coefficient of thermal expansion) aligns well with polyimide and copper, reducing delamination risks during thermal cycling. For high-performance led pcb assemblies and compact power modules, this reinforcement layer maintains structural accuracy and prevents shifting of mounted components—a critical demand in advanced pcb services.

Seamless Integration Into Standard Assembly Processes

The stiffener is compatible with pick-and-place equipment, reflow soldering, and punching operations. Its shape and bonding method can be tailored for integration at specific stages of the production line without disrupting cycle times. Adhesive-backed or pre-punched aluminum formats are available for streamlined use. These features are particularly advantageous for flex pcb configurations requiring high-volume production where mechanical alignment must be preserved. Pcb suppliers offering custom lamination and cutting further enhance deployment flexibility.

Use Scenarios

Consumer Electronics Designers Reinforcing Connector Interfaces

Product engineers designing compact devices such as smartphones, tablets, or handheld sensors often face challenges related to connector reliability. Repeated mating cycles and user interaction cause stress on the FPC substrate. By integrating this aluminum stiffener, they ensure secure flatness and prevent peeling or cracking. As part of end-to-end pcb services, it adds no active function but improves the mechanical quality of flexible pcb assemblies sourced from reliable pcb suppliers.

Automotive Engineers Building Dashboard Flex Modules

FPCs used in automotive dashboards or control units must endure significant vibration and temperature fluctuation. Engineers adopt aluminum stiffeners in zones with press-fit connectors or microcontrollers to ensure board flatness and thermal consistency. In conjunction with ruggedized flexible circuit board designs, this mechanical reinforcement offers long-term durability and ease of final assembly—especially when coordinated with a trusted pcb manufacturer capable of precision pre-bonding and shape optimization.

Lighting Module Integrators Adding Thermal Protection Layers

In LED strips and lighting control units, certain components generate hotspots or require stable mounting positions. Integrators use this aluminum stiffener to support those regions while dissipating heat through conduction. It is often used under driver ICs or as a backplate in led pcb assemblies where both heat and structure need to be managed without adding excessive thickness. Its integration into flex pcb systems ensures consistent light output and reduces thermal damage during extended operation.

About Us

This circuit board provider specializes in comprehensive fabrication and value-added services, including rigid, flexible, and mixed-structure PCB configurations. With capabilities spanning aluminum, FR4, polyimide, and composite materials, the team supports industries from automotive electronics to lighting systems and consumer devices. Recognized among dependable pcb suppliers, the manufacturer offers tailored pcb services such as stiffener integration, selective lamination, and high-precision routing. By combining material engineering with production agility, the company helps clients bring complex flexible pcb and rigid-flex products to market quickly while maintaining consistency, accuracy, and long-term performance standards.

Send your aluminum stiffener flexible pcb request and receive custom specifications today!

FAQ

Can this aluminum stiffener be pre-bonded before shipping?

Yes, pre-bonding is available using thermal or pressure-sensitive adhesives based on design specs.

Is it compatible with automated assembly processes?

The stiffener is designed to work with SMT lines, punching equipment, and reflow soldering workflows.

Can insulation be applied to the aluminum surface?

Yes, an insulating film or anodizing treatment can be added if electrical isolation is required.

What thicknesses are available for the aluminum backing?

Standard options range from 0.3mm to 1.5mm; custom dimensions can be manufactured.

Are there size limitations for stiffener bonding areas?

Bonding zones can be fully customized; only the FPC layout and component clearances need to be considered.