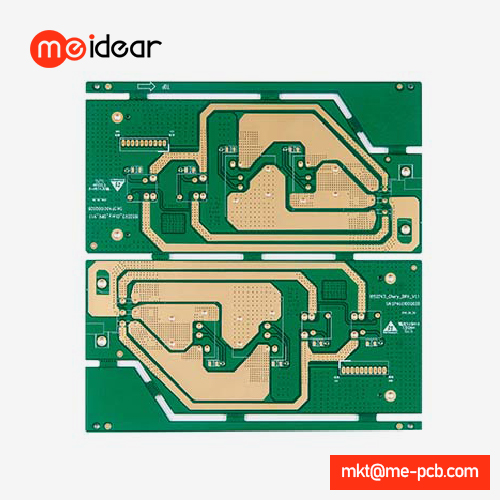

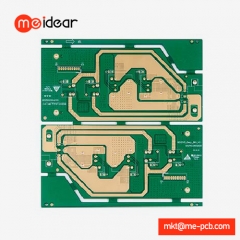

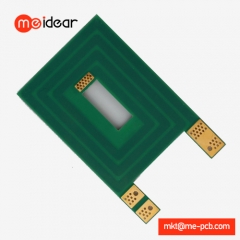

Heavy Copper PCB

Super heavy copper pcb

2L

Board thickness: 2.0mm

Outer copper thickness: 8 OZ

Min hole: 0.30mm

Min line width/line spacing: 12mil

Surface treatment: Immersion Gold

Product use: car power board

Board thickness: 2.0mm

Outer copper thickness: 8 OZ

Min hole: 0.30mm

Min line width/line spacing: 12mil

Surface treatment: Immersion Gold

Product use: car power board

Description

Designed For Extreme Current Handling And Heat Dissipation

This super heavy copper PCB is developed for high-load electrical environments where traditional copper thickness fails to meet performance or safety requirements. The 10oz copper layers allow for significant current-carrying capability, low resistance, and robust thermal performance. It is engineered for engineers, energy system integrators, and control cabinet manufacturers who need reinforced board structures in demanding power conditions. Recognized by industrial pcb suppliers, this board is also valued for its long-term durability in intensive applications supported by advanced pcb services.

Copper Weight And Multi-Layer Configuration

The core characteristic of this board is its 10oz (approximately 350μm) copper thickness, supported across multiple layers to ensure uniform heat dissipation and current flow. The base material is high-Tg FR4, which provides enhanced mechanical strength and temperature resistance. Vias are plated to withstand the electro-thermal stress caused by high current surges. Layer stack-up is customizable, and board finishes like ENIG and HASL are available. These parameters allow the board to integrate with flexible circuit board systems when hybrid power modules are involved, making it relevant to both pcb manufacturer and flex pcb applications.

Applications In Power Distribution, Control, And Conversion

This PCB is frequently implemented in converters, high-power rectifiers, electric vehicle power modules, and renewable energy systems. Its ability to deliver stable voltage under load and manage thermal feedback makes it ideal for rugged field environments. Designers of power pcb systems for industrial motors, HVAC controllers, and off-grid solar inverters rely on such boards for performance consistency. It is an established choice for OEMs sourcing from global pcb suppliers with requirements for specialized pcb services.

Product Advantages

High Copper Weight Enables Enhanced Current Density

With 10oz copper layers, this board supports extremely high current without overheating or trace degradation. Compared to standard boards, its capacity to distribute power over wide traces makes it suitable for demanding electrical routes and power bus networks. Thermal efficiency improves as the copper itself acts as a heat spreader, reducing dependency on external heat sinks. It’s frequently selected by pcb manufacturer partners working on scalable power pcb designs for infrastructure and heavy-duty applications.

Thermal Expansion Stability With High-Tg FR4 Base

Thermal cycling in high-power systems causes board deformation and delamination if the substrate is not adequately selected. This board uses high-Tg FR4, allowing it to operate consistently under elevated temperatures. The copper-to-substrate adhesion is reinforced through controlled lamination processes, supporting dimensional stability and protecting the plated through-holes. This becomes crucial when integrating with flexible pcb assemblies in modular systems, where alignment and heat resistance matter for both pcb services and device reliability.

Reinforced Layer Bonding For Structural Integrity

Super heavy copper layers can impose mechanical stress during handling or during high-current operation. This board’s manufacturing process includes reinforced layer bonding using high-pressure pressing and full-depth resin fill to prevent separation or blistering. Edge routing remains clean even in multi-panel configurations. These factors contribute to longer product lifespans in mission-critical circut board installations and make the product suitable for integration into hybrid flex pcb systems where mechanical reliability is essential.

Use Scenarios

Power Equipment Engineers Building Inverter Control Boards

Engineers developing inverter circuits for industrial motors, HVAC, or generator units need PCBs that can support repetitive current spikes and temperature cycling. This super heavy copper board withstands high DC and AC loads without degrading trace integrity. Used in standalone control cabinets and embedded units, it is sourced from reliable pcb suppliers that offer customized pcb services including hole plating and thermal simulation data.

Renewable Energy Developers Integrating Battery Management Systems

For off-grid or hybrid power systems, battery management units and DC-DC converters demand PCBs that can handle high amperage with minimal loss. This 10oz power pcb offers low internal resistance and ensures consistent voltage delivery under full-load operation. Developers in solar storage or wind-powered systems collaborate with pcb manufacturer teams to specify trace paths and via reinforcement for energy-dense modules that may also include flexible circuit board interconnects.

Automotive Design Consultants Specifying Electric Drive Controllers

In electric vehicle subsystems such as drive units or onboard chargers, thermal regulation and structural integrity are core to PCB selection. Consultants working on powertrain integration specify these super heavy copper boards for their high thermal mass and layered power routing. The board’s reliability in temperature swings and vibrational loads makes it a dependable choice when designing high-capacity led pcb or hybrid flex pcb configurations for mobile use.

About Us

With extensive experience in the circuit board industry, this supplier provides advanced manufacturing services for rigid, flexible, and heavy copper PCBs. The company’s capabilities cover the full production cycle—from prototyping to mass production—across multiple board types including multilayer, high-frequency, and super thick copper configurations. Known among professional pcb suppliers, they offer application-focused pcb services tailored to high-demand sectors such as power electronics, automotive control, LED lighting, and renewable energy systems. Their expertise extends to process controls, copper weight management, and advanced lamination—all delivered under strict quality standards. Serving clients worldwide, they are a trusted pcb manufacturer for both standardized and fully customized flexible pcb solutions.

Request your custom super heavy copper power pcb design from our engineering team today!

FAQ

What is the maximum copper thickness supported?

Copper weight up to 10oz per layer is supported; custom requests beyond this are evaluated on demand.

Is this board compatible with multilayer power designs?

Yes, it supports multilayer configurations with plated vias and controlled impedance.

Can I request thermal simulation before production?

Yes, thermal and electrical simulations can be provided during the engineering review process.

What surface finishes are available for these boards?

Standard options include ENIG, HASL, and OSP, compatible with high-current applications.

What is the typical production time for heavy copper PCBs?

Lead time ranges from 10–18 working days depending on layer count and copper weight.