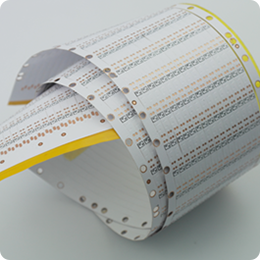

Single Sided Flexible PCB

Manufacturing with Ultra-Thin, Flexible Printed Circuit Boards

Manufacturing with Ultra-Thin, Flexible Printed Circuit Boards.

China professional OEM manufacturing transparent pcb board.

Custom Transparent Polyimide PCB Cable Flexible FPC

Flexible PCB for LED FPC.

China professional OEM manufacturing transparent pcb board.

Custom Transparent Polyimide PCB Cable Flexible FPC

Flexible PCB for LED FPC.

Description

Extra thin PCB and ultra-thin FPCB

Ultra-thin base materialsUltra-thin base materials take PCB miniaturization to the next l-evel.

Flexible and rigid ultra-thin base materials enable highly reliable, thinner PCBs.

Tips for designing with Ultra-Thin, Flexible Printed Circuit Boards

Space savings, greater reliability, low mass, and high ductility are some of the advantages offered by flexible PCBs,

but designers must also prepare for their complexity.

Flexible printed circuit boards (PCBs) aren’t much different than rigid boards during the design phase, except that the designer must account for the mechanical complexity associated with flex circuits. For instance, a flexible PCB can tear if flexed beyond its capability during installation.

Therefore, it’s very important to create a mechanical model of the PCB and test it for a proper fit, before taking up the electrical design. This would also involve testing the ergonomics of the installation, any misalignments, and servicing. In addition, it necessitates that designers understand the different types of flex circuits available and the way they work.

Designers shape flex circuits to fit where it’s impossible to use any other type of PCB. One can think of flex circuits as being a combination of the ordinary PCB and round wires, while exhibiting their individual benefits. With flex circuits, one can retain the precision, density, and repeatability of regular PCBs, and still achieve unlimited freedom for packaging geometry.

Big size FPC(400*1400mm) - Multilayer/Rigid-Flex Circuits

With flexible substrates, it is possible to create PCBs that fold to reduce the surface area and volume needed to house the PCB and thus increase the integration density. Using thinner flex materials rather than traditional thick FR4 materials can reduce the space needed for the PCB even more.

| Extra Thin Flex Board Capability Base material: PI Ultrathin Board Thickness: 0.1mm~0.3mm Copper thickness: 0.5 OZ, 1.0 OZ, 1.5 OZ, 2.0 OZ Outline: Laser, punching Coverlay: Bare/White/Black/Blue/Green/Red PI film Legend/Silkscreen Color: Black/White Surface finishing: Immersion Gold, OSP Max Panel size: 1500*500mm Packing: Vacuum Samples L/T: 7~9 Days MP L/T: 8~10 Days |

|

Please contact us for more information about extra thin PCB.

Ultra-thin Printed Circuit Board | Extra Thin PCB | Ultrathin FR4 Circuit | 0.16mm thickness board Ultra-thin PCB by Meidear PCB

Email Address: mkt@me-pcb.com

Also you learn more about us from Linkedin.

https://www.linkedin.com/feed/update/urn:li:activity:6665952118702247936/