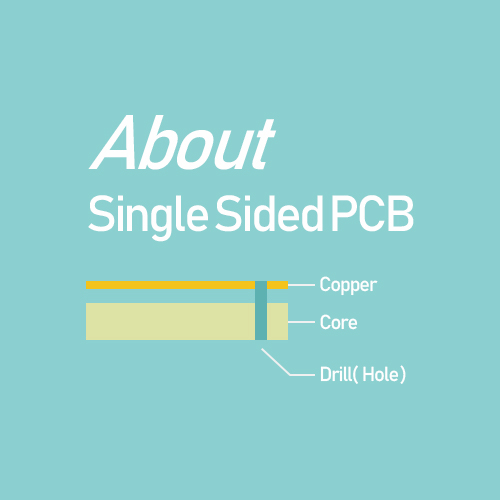

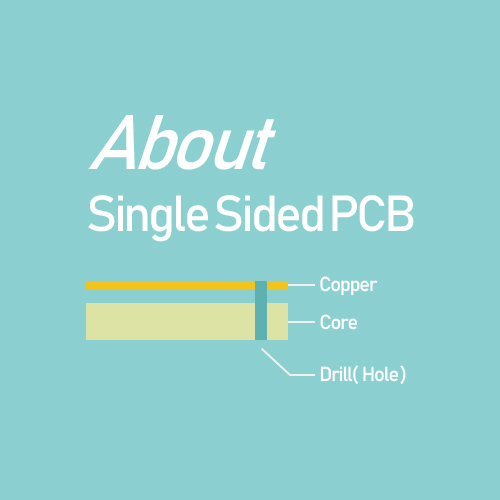

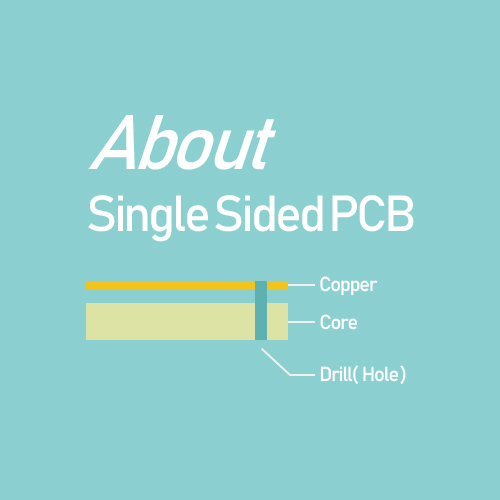

Single-double Sided PCB

What is FR4 single sided PCB

Copper thicknesses: 1Oz 2Oz 1.5Oz, 3Oz

copper-clad laminate (CCL)

Core: glass-reinforced epoxy laminate material

copper-clad laminate (CCL)

Core: glass-reinforced epoxy laminate material

Description

What is FR-4(FR4) PCB material?

FR-4 (or FR4) is a NEMA grade designation for glass-reinforced epoxy laminate material. FR-4 is a composite material composed of woven fiberglass cloth with an epoxy resin binder that is flame resistant (self-extinguishing).

"FR" stands for flame retardant, and does not denote that the material complies with the standard UL94V-0 unless testing is performed to UL 94, Vertical Flame testing in Section 8 at a compliant lab. The designation FR-4 was created by NEMA in 1968.

FR-4 epoxy resin systems typically employ bromine, a halogen, to facilitate flame-resistant properties in FR-4 glass epoxy laminates.

Most printed circuit boards are manufactured using glass-reinforced epoxy laminate as the substrate. While there are a wide variety of laminates available on the market, FR-4 is both versatile and well-accepted as a standard material for PCB manufacture. FR-4 functions well as an electrical insulator, and has a good strength-to-weight ratio, and is flame resistant.

The standard FR-4 material that is used in our products is a high temperature, high Td, low CTE 150Tg material.

In a typical PCB, the core provides the rigidity and the foundation on which the PCB traces can be ‘printed’ onto. In addition, the FR4 core and laminates form the electrical isolation separating copper layers.

What is single sided PCB?

Product Advantages

Reliable Thermal and Mechanical Properties

FR4 boards produced by Meidear use high-grade glass epoxy laminates with optimized heat tolerance and flame resistance. The substrate remains dimensionally stable under elevated temperatures, an essential feature for both automated and manual soldering environments. Its low coefficient of thermal expansion minimizes warping during thermal cycling, allowing predictable performance in operation. These qualities make the FR4 structure highly favorable among pcb manufacturing companies that prioritize long-term circuit durability and low failure rates in static or modestly dynamic environments. For users seeking robust pcb circuit board materials without multilayer complexity, FR4 single-sided options offer a dependable balance of strength and cost.

Simplified Signal Routing and Maintenance

The single-sided configuration allows designers to plan circuits on one surface, avoiding crossover challenges or inter-layer registration errors. This simplifies both layout design and manufacturing steps, especially in initial testing or revision cycles. Additionally, visible access to all components and traces improves inspection and maintenance. Meidear’s alignment accuracy in copper patterning and pad exposure ensures each board can be fabricated to customer specification quickly, enabling streamlined cycles within a pcb prototype service model. This advantage shortens development timeframes while keeping design flexibility open.

Material Versatility and Broad Compatibility

The use of FR4 enables the product to meet common industry electrical and mechanical standards. Its flame retardancy and electrical insulation properties meet the baseline requirements for many commercial and industrial electronics. Meidear sources FR4 with verified quality and processes it under controlled panelization, punching, and plating operations. These methods make the board adaptable across projects requiring compatibility with global compliance frameworks. Through its role among established pcb fabrication companies, Meidear offers consistent build reliability and layout flexibility with every FR4 pcb circuit board produced.

Use Scenarios

Basic Signal Carrier Boards in Entry-Level Devices

The simplicity of a single-layer FR4 board suits devices that require basic routing of signals or power without internal layer separation. These boards are commonly applied in cost-sensitive electronics, where functionality is delivered through minimal component integration. Because of its flame-retardant epoxy core and mechanical strength, this type of pcb circuit board supports basic use-cases without requiring multilayer complexity. Clients who work with pcb fabrication companies like Meidear benefit from standard materials that support direct routing for LED drivers, power switches, or basic sensors.

Educational and Research Prototyping

In early-stage projects, such as university research, lab testing, or early concept validation, FR4 single-layer PCBs provide a low-risk entry point. These boards allow learners and engineers to visualize and modify layouts easily due to their exposed single-side traces. Meidear supports these applications by offering flexible ordering and data file handling, allowing participants to use a reliable pcb prototype service without volume commitments. For environments focused on speed and clarity in circuit design, the FR4-based layout structure is both accessible and functional.

Functional Mock-Ups and Low-Speed Modules

When building functional mock-ups or modules with low-frequency signals, a single-layer board meets performance needs without overdesign. For basic relays, user interfaces, or manual control systems, the FR4 board offers sufficient insulation and form stability. Its core material resists moisture and maintains flatness under standard handling. Meidear provides such boards in small batches with optional copper thicknesses to support these modest demands. As part of its comprehensive service scope, the company ensures this pcb circuit board remains a practical solution in cost-constrained mock-up projects backed by verified pcb manufacturing companies.

About Us

Established in 2014, Shenzhen Meidear Co., Limited is a manufacturer of circuit boards and assembly services for various electronics sectors. The company focuses on producing single-layer, multilayer, and rigid-flex PCBs with applications across lighting, automation, and customized systems. As one of the recognized pcb fabrication companies, Meidear supports prototyping, small-batch, and medium-volume production using standard materials such as FR4 and aluminum-based laminates. Its facilities integrate full pcb prototype service capabilities, with layout file compatibility in formats like CAM350, Protel, and PowerPCB. Meidear handles order data securely and provides controlled surface treatment, copper layering, and product delivery processes. With a global logistics network and file review support, the company continues to serve clients with consistent, specification-driven builds across a wide spectrum of circuit board needs.

FAQ

What material is used in this board?

This product uses FR4, a glass-reinforced epoxy laminate, as the base for the pcb circuit board.

Is this a single-sided PCB?

Yes, the board has one copper layer printed on a rigid FR4 core, following a standard PCB fabrication format.

What copper thicknesses are available?

Options include 1Oz, 1.5Oz, 2Oz, and 3Oz, determined by layout requirements.

Can I request a prototype version of this board?

Yes, Meidear supports prototyping without fixed quantity thresholds through its pcb prototype service.

Which design files are accepted for production?

Meidear accepts files in CAM350, Protel 99SE, and PowerPCB formats, as part of its support for clients of all sizes in the pcb manufacturing companies space.

Submit your single-layer FR4 layout today and build your next pcb circuit board with Meidear’s expert PCB fabrication support!

FR-4 (or FR4) is a NEMA grade designation for glass-reinforced epoxy laminate material. FR-4 is a composite material composed of woven fiberglass cloth with an epoxy resin binder that is flame resistant (self-extinguishing).

"FR" stands for flame retardant, and does not denote that the material complies with the standard UL94V-0 unless testing is performed to UL 94, Vertical Flame testing in Section 8 at a compliant lab. The designation FR-4 was created by NEMA in 1968.

FR-4 epoxy resin systems typically employ bromine, a halogen, to facilitate flame-resistant properties in FR-4 glass epoxy laminates.

Most printed circuit boards are manufactured using glass-reinforced epoxy laminate as the substrate. While there are a wide variety of laminates available on the market, FR-4 is both versatile and well-accepted as a standard material for PCB manufacture. FR-4 functions well as an electrical insulator, and has a good strength-to-weight ratio, and is flame resistant.

The standard FR-4 material that is used in our products is a high temperature, high Td, low CTE 150Tg material.

In a typical PCB, the core provides the rigidity and the foundation on which the PCB traces can be ‘printed’ onto. In addition, the FR4 core and laminates form the electrical isolation separating copper layers.

What is single sided PCB?

Product Advantages

Reliable Thermal and Mechanical Properties

FR4 boards produced by Meidear use high-grade glass epoxy laminates with optimized heat tolerance and flame resistance. The substrate remains dimensionally stable under elevated temperatures, an essential feature for both automated and manual soldering environments. Its low coefficient of thermal expansion minimizes warping during thermal cycling, allowing predictable performance in operation. These qualities make the FR4 structure highly favorable among pcb manufacturing companies that prioritize long-term circuit durability and low failure rates in static or modestly dynamic environments. For users seeking robust pcb circuit board materials without multilayer complexity, FR4 single-sided options offer a dependable balance of strength and cost.

Simplified Signal Routing and Maintenance

The single-sided configuration allows designers to plan circuits on one surface, avoiding crossover challenges or inter-layer registration errors. This simplifies both layout design and manufacturing steps, especially in initial testing or revision cycles. Additionally, visible access to all components and traces improves inspection and maintenance. Meidear’s alignment accuracy in copper patterning and pad exposure ensures each board can be fabricated to customer specification quickly, enabling streamlined cycles within a pcb prototype service model. This advantage shortens development timeframes while keeping design flexibility open.

Material Versatility and Broad Compatibility

The use of FR4 enables the product to meet common industry electrical and mechanical standards. Its flame retardancy and electrical insulation properties meet the baseline requirements for many commercial and industrial electronics. Meidear sources FR4 with verified quality and processes it under controlled panelization, punching, and plating operations. These methods make the board adaptable across projects requiring compatibility with global compliance frameworks. Through its role among established pcb fabrication companies, Meidear offers consistent build reliability and layout flexibility with every FR4 pcb circuit board produced.

Use Scenarios

Basic Signal Carrier Boards in Entry-Level Devices

The simplicity of a single-layer FR4 board suits devices that require basic routing of signals or power without internal layer separation. These boards are commonly applied in cost-sensitive electronics, where functionality is delivered through minimal component integration. Because of its flame-retardant epoxy core and mechanical strength, this type of pcb circuit board supports basic use-cases without requiring multilayer complexity. Clients who work with pcb fabrication companies like Meidear benefit from standard materials that support direct routing for LED drivers, power switches, or basic sensors.

Educational and Research Prototyping

In early-stage projects, such as university research, lab testing, or early concept validation, FR4 single-layer PCBs provide a low-risk entry point. These boards allow learners and engineers to visualize and modify layouts easily due to their exposed single-side traces. Meidear supports these applications by offering flexible ordering and data file handling, allowing participants to use a reliable pcb prototype service without volume commitments. For environments focused on speed and clarity in circuit design, the FR4-based layout structure is both accessible and functional.

Functional Mock-Ups and Low-Speed Modules

When building functional mock-ups or modules with low-frequency signals, a single-layer board meets performance needs without overdesign. For basic relays, user interfaces, or manual control systems, the FR4 board offers sufficient insulation and form stability. Its core material resists moisture and maintains flatness under standard handling. Meidear provides such boards in small batches with optional copper thicknesses to support these modest demands. As part of its comprehensive service scope, the company ensures this pcb circuit board remains a practical solution in cost-constrained mock-up projects backed by verified pcb manufacturing companies.

About Us

Established in 2014, Shenzhen Meidear Co., Limited is a manufacturer of circuit boards and assembly services for various electronics sectors. The company focuses on producing single-layer, multilayer, and rigid-flex PCBs with applications across lighting, automation, and customized systems. As one of the recognized pcb fabrication companies, Meidear supports prototyping, small-batch, and medium-volume production using standard materials such as FR4 and aluminum-based laminates. Its facilities integrate full pcb prototype service capabilities, with layout file compatibility in formats like CAM350, Protel, and PowerPCB. Meidear handles order data securely and provides controlled surface treatment, copper layering, and product delivery processes. With a global logistics network and file review support, the company continues to serve clients with consistent, specification-driven builds across a wide spectrum of circuit board needs.

FAQ

What material is used in this board?

This product uses FR4, a glass-reinforced epoxy laminate, as the base for the pcb circuit board.

Is this a single-sided PCB?

Yes, the board has one copper layer printed on a rigid FR4 core, following a standard PCB fabrication format.

What copper thicknesses are available?

Options include 1Oz, 1.5Oz, 2Oz, and 3Oz, determined by layout requirements.

Can I request a prototype version of this board?

Yes, Meidear supports prototyping without fixed quantity thresholds through its pcb prototype service.

Which design files are accepted for production?

Meidear accepts files in CAM350, Protel 99SE, and PowerPCB formats, as part of its support for clients of all sizes in the pcb manufacturing companies space.

Submit your single-layer FR4 layout today and build your next pcb circuit board with Meidear’s expert PCB fabrication support!