Thermoelectric Separation Technology of Copper Core PCB

Views : 2426

Author : meidear

Update time : 2020-04-23 11:02:00

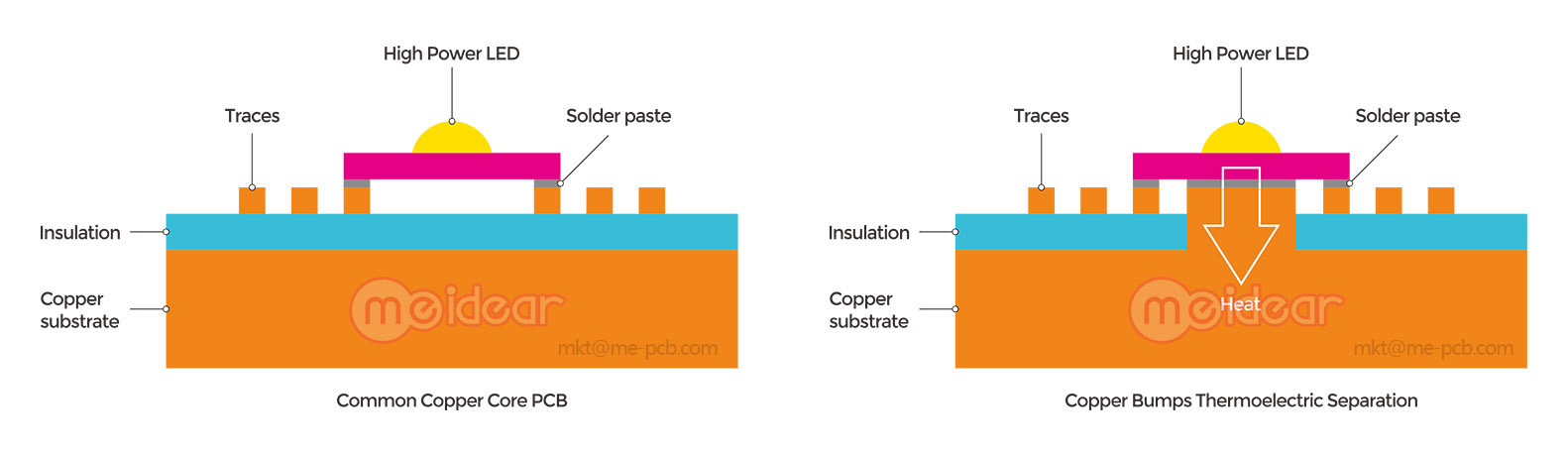

What is the Thermoelectric Separation Substrate?

The circuit part and the thermal layer part of the substrate are on different circuit layers, and the thermal layer part directly contacts the heat dissipation part of the lamp bead to achieve the best heat dissipation (zero thermal resistance) effect. And the material of the substrate is generally the copper substrate.

Super High Thermal Conductive Based Board: 3.0 W/M.K

Advantages:

1. Selecting the copper substrate: the density is high, the substrate itself has strong heat carrying capacity, and the heat conduction and heat dissipation are good.

2. Adopting the thermoelectric separation structure: contact the lamp bead with zero thermal resistance, reduce the weakness of lamp bead light and extend the life of lamp bead to an extreme.

3. The density of the copper substrate is high, and the heat carrying capacity is strong, and the volume is smaller under the same power.

4. Suitable for matching single high-power lamp beads, especially COB package, making the lamp to achieve better results.

5. According to different needs, various table treatments (immersion gold, OSP, spray tin, silver plating, immersion silver + silver plating) can be carried out, and the surface treatment layer has excellent reliability.

6. Different structures can be made according to the different design needs of the lamps (copper bumps, copper concave block, paralleled thermal.

2. Adopting the thermoelectric separation structure: contact the lamp bead with zero thermal resistance, reduce the weakness of lamp bead light and extend the life of lamp bead to an extreme.

3. The density of the copper substrate is high, and the heat carrying capacity is strong, and the volume is smaller under the same power.

4. Suitable for matching single high-power lamp beads, especially COB package, making the lamp to achieve better results.

5. According to different needs, various table treatments (immersion gold, OSP, spray tin, silver plating, immersion silver + silver plating) can be carried out, and the surface treatment layer has excellent reliability.

6. Different structures can be made according to the different design needs of the lamps (copper bumps, copper concave block, paralleled thermal.

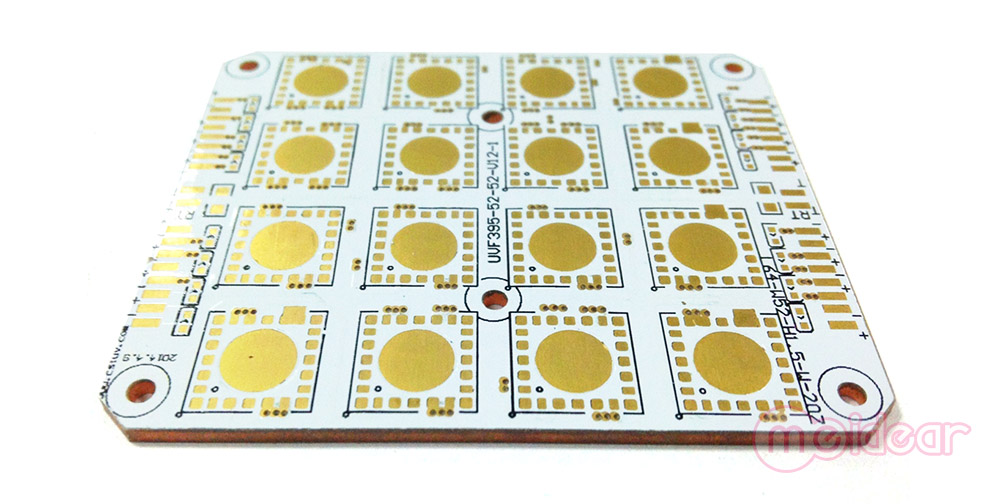

48W Thermopile copper base plate

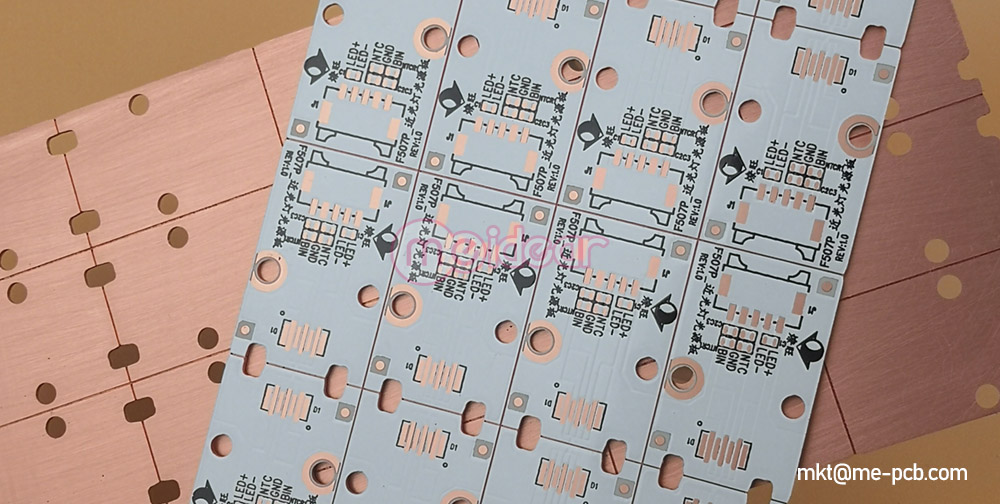

Headlight Lower Beam light source board

Thermoelectric separation copper substrate for Headlight Lower Beam

Meidear pcb mainly produces all kinds of high-end metal core PCB:

per the type of metal bases including copper base, aluminum base, aluminum base, steel base; according to the structure type of products including thermoelectricity separation, hard and soft combine, single or double sided multi-layer; the products are widely used in the high-tech fields such as automotive electronics.

Shenzhen China Thermoelectric separation MPCB factory

Shenzhen Meidear Co., Limited can make Copper Based PCB, Thermoelectric Separation Copper Based PCB, LED PCB lighting, Metal Core PCB and Quick turn MPCB prototype assembly with high quantity.

Email: mkt@me-pcb.com

Aluminum PCB, Metal Core PCB, Ceramic PCB, Copper Based PCB, LED PCB, Flex PCB

Related News

The Prevalence of Mid-High TG Materials in Multilayer PCB Fabrication

Jul .17.2025

In the manufacturing of multilayer printed circuit boards (PCBs), mid-high glass transition temperature (TG) materials have become the norm. This article aims to explore the reasons behind this industry preference.

NEWS FLASH: Guangzhou International Lighting Exhibition 2025 Signals Major Shifts for PCB Industry in Lighting & Beyond

Jun .12.2025

Guangzhou, China – June 12, 2025

(Reporting Live from Guangya Expo 2025)

(Reporting Live from Guangya Expo 2025)

Comparison of LDI and CCD Exposure Systems

Apr .03.2025

In the PCB (Printed Circuit Board) manufacturing process, exposure is a critical step. Many PCB manufacturers like meidearpcb utilize CCD semi-automatic exposure machines for this process.

LED lighting PCB (Printed Circuit Board) Solutions

Jan .01.2025

LED lighting PCB (Printed Circuit Board) solutions

CEM-3 Thermal conductive material

IMS pcb Flexible pcb Copper-base pcbs

CEM-3 Thermal conductive material

IMS pcb Flexible pcb Copper-base pcbs