What is Solder mask bridge?

Views : 3877

Author : meidear

Update time : 2020-07-16 12:02:53

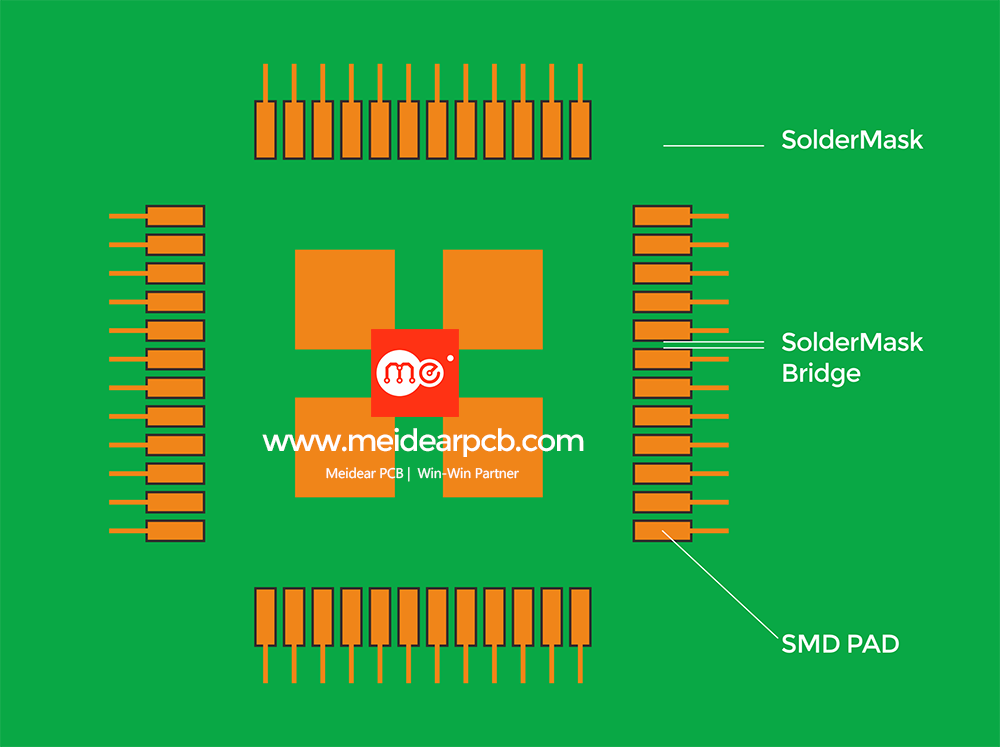

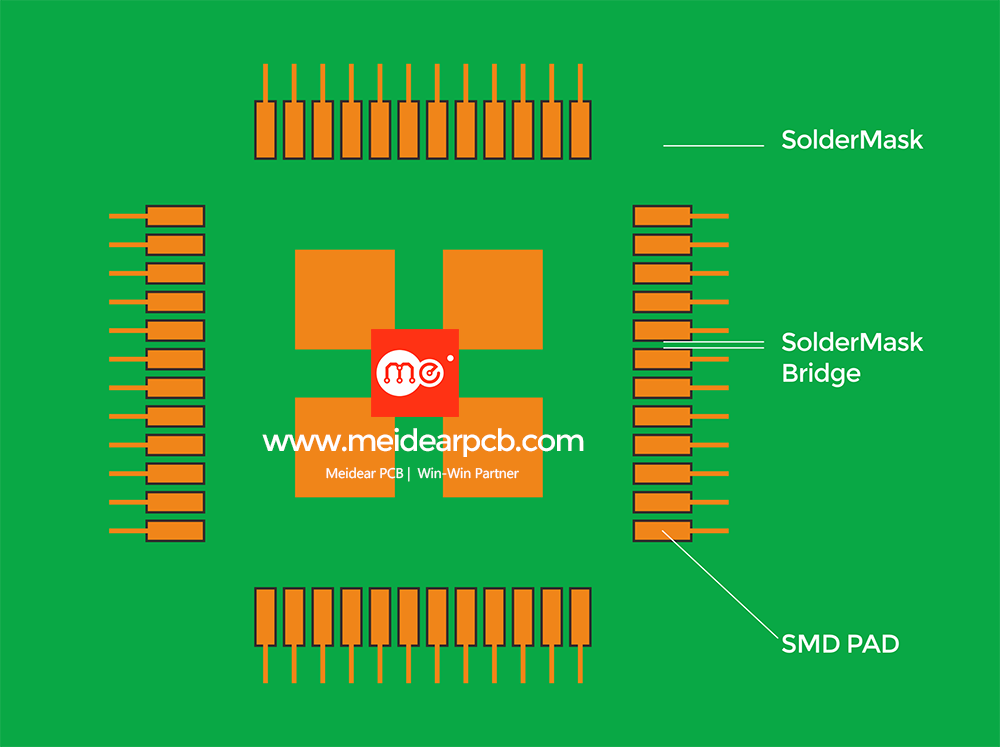

Solder Mask Bridge:

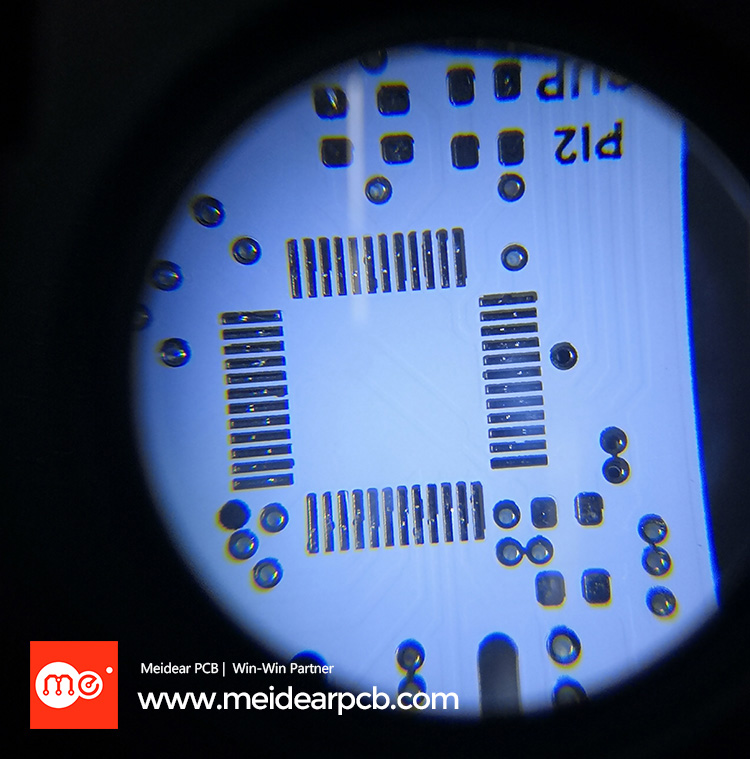

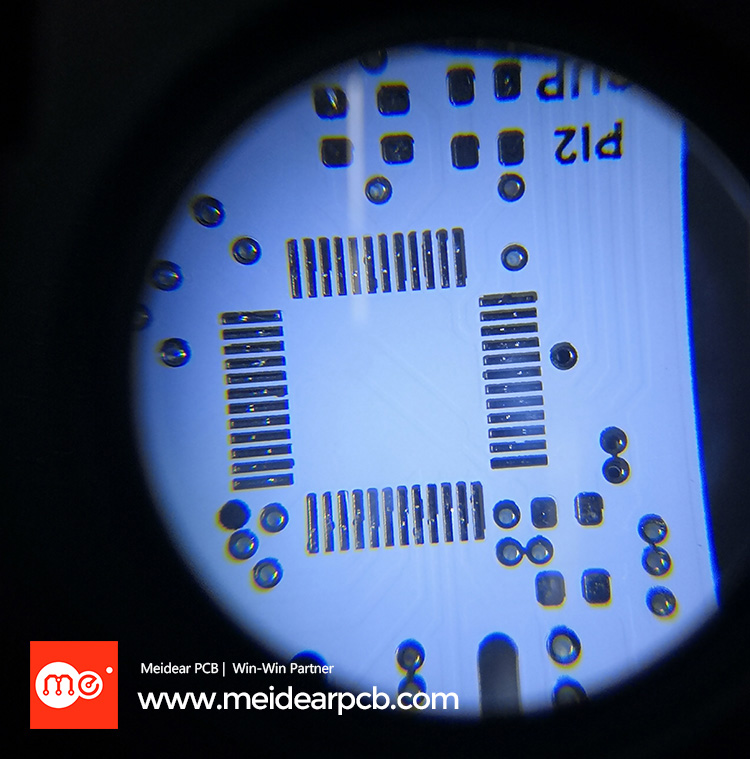

The oil between two pins of component is solder mask bridge, generally refers to intensive IC pin (check the below picture). If the distance of pin is too small, it will be recommended to cancel the solder mask bridge and take advantage of solder mask opening technology.

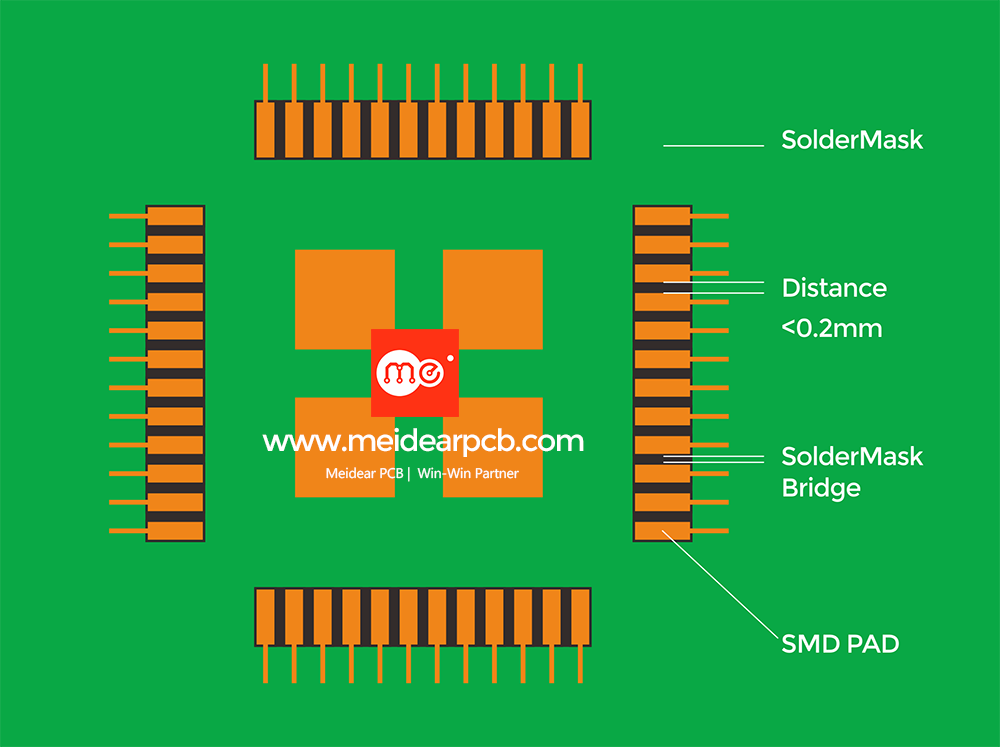

The solder resist between the SMD pads is called solder mask bridge (solder mask dam), which serves to prevent bridging and short circuit when welding. Sometimes the solder mask bridge breaking off happens in many printed circuit board companies, greatly affecting the product quality and production efficiency. With the rapid development of PCB industry, the requirements of customers are getting higher and higher.

The oil between two pins of component is solder mask bridge, generally refers to intensive IC pin (check the below picture). If the distance of pin is too small, it will be recommended to cancel the solder mask bridge and take advantage of solder mask opening technology.

The solder resist between the SMD pads is called solder mask bridge (solder mask dam), which serves to prevent bridging and short circuit when welding. Sometimes the solder mask bridge breaking off happens in many printed circuit board companies, greatly affecting the product quality and production efficiency. With the rapid development of PCB industry, the requirements of customers are getting higher and higher.

The main reason of solder mask bridge breaking off is that the intensity of UV decreases rapidly with transmission depth of solder mask ink, and when the ink is more than a certain thickness, it will not be fully photo-polymerized, so undercut and solder mask bridge breaking off happen when developing. Meantime, the exposure energy, developing time, precure time and so on will have an influence on breaking off solder mask bridge.

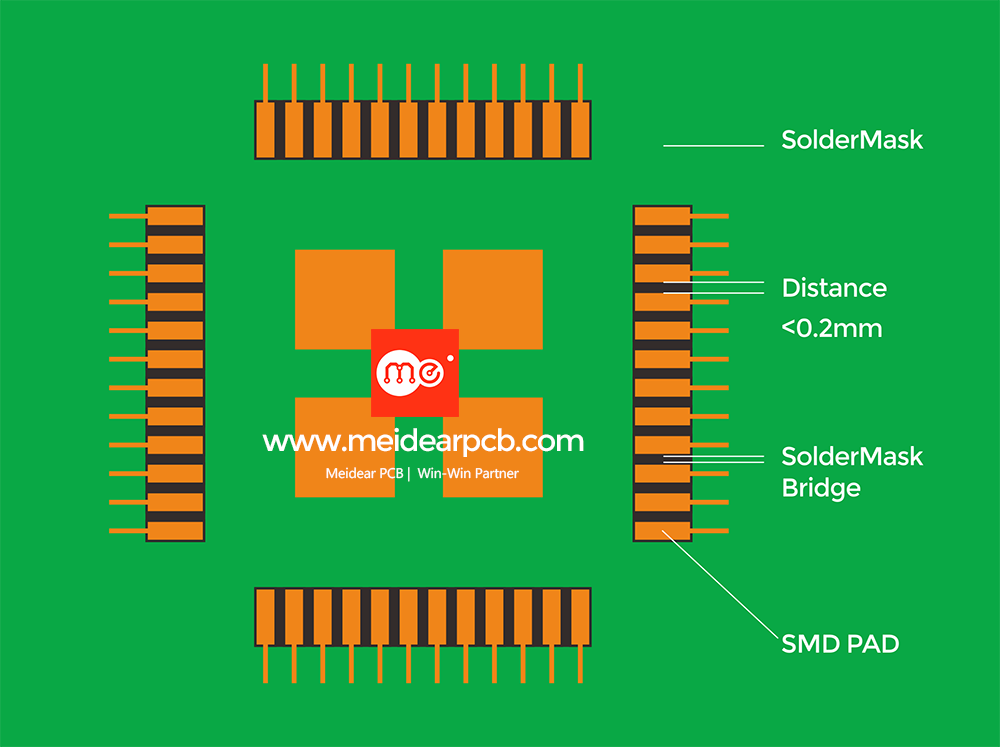

Solder Mask Openings:

Meidear PCB can accept the min distance between IC pins is 0.2mm (check the below picture), if the distance less than 0.2mm, we recommend to do solder mask openings.

Related News

The Prevalence of Mid-High TG Materials in Multilayer PCB Fabrication

Jul .17.2025

In the manufacturing of multilayer printed circuit boards (PCBs), mid-high glass transition temperature (TG) materials have become the norm. This article aims to explore the reasons behind this industry preference.

NEWS FLASH: Guangzhou International Lighting Exhibition 2025 Signals Major Shifts for PCB Industry in Lighting & Beyond

Jun .12.2025

Guangzhou, China – June 12, 2025

(Reporting Live from Guangya Expo 2025)

(Reporting Live from Guangya Expo 2025)

Comparison of LDI and CCD Exposure Systems

Apr .03.2025

In the PCB (Printed Circuit Board) manufacturing process, exposure is a critical step. Many PCB manufacturers like meidearpcb utilize CCD semi-automatic exposure machines for this process.

LED lighting PCB (Printed Circuit Board) Solutions

Jan .01.2025

LED lighting PCB (Printed Circuit Board) solutions

CEM-3 Thermal conductive material

IMS pcb Flexible pcb Copper-base pcbs

CEM-3 Thermal conductive material

IMS pcb Flexible pcb Copper-base pcbs